Rational and competent choice of dental burs

Dental burs are used for various types of work related to hard dental tissues, as well as the treatment of caries and orthopedic structures. You can buy dental burs from a wide range of products.

When you contact us, qualified specialists will answer your questions and tell you what priorities you should pay attention to when choosing the right dental burs.

Classification of dental carbide burs and other types of rotary instruments

Based on the type of materials used, rotating instruments are divided into dental diamond burs, steel, carbide, carborundum, and silicone. Each of these types is intended for professional performance of certain types of work.

Depending on the selected tip, dental burs are classified into 3 types, which in turn differ in diameter:

- straight - 2.35 mm;

- corner – 2.35 mm;

- turbine - 1.6 mm.

Burs also vary in length; by contacting our company, you can fully count on professional assistance in choosing high-quality dental equipment.

If we talk about shade markings, then in accordance with current ISO standards, rotary tools are divided according to the color of the marking:

1. Black – for use at the 1st stage of preparation.

2. Green, blue - for precise and subtle giving of the required shape.

3. Red – for final formation of cavity/bevels (only on carbide/diamond bur).

Burs in therapeutic dentistry

In this area, wheel-shaped, cone-shaped, pear-shaped, spherical burs, differing in the size of the working part, are most often used. As a rule, burs intended for therapeutic dentistry have a head diameter of 1-3 mm. But, in practice, there are smaller/larger tools.

Burs in surgical dentistry

This type of instrument is used for preparing bones, hard dental tissues, removing root remains, and separating impacted/dystopic wisdom teeth.

Thanks to a decent level of performance characteristics, surgical burs allow dental procedures to be carried out with particular care and precision. The diameter of the working part of this tool can be from 1.6 to 2.7 mm.

The choice of burs also depends on the type of dental treatment being performed:

- enamel preparation – carbide/diamond with turbine working area;

- when working with deep cavities, use spherical steel burs;

- finishing processing of fillings made of composite material - diamond rotating tools, characterized by fine grain;

- preparation of dentin - it is recommended to use large carbide pear-shaped/spherical burs.

From us you can also buy NTI burs, which are manufactured by a German manufacturer that adheres to an automated process and the use of modern High-Tech innovations.

If you need to buy MonAlit burs, which are famous for their strength, performance and long service life, then we suggest using the contacts provided.

Diamond or carbide: which bur is better?

When answering this question, we first of all think about whether our bur is new or old, whether it is sharp or blunt. Although, in fact, the answer to this question must consist of many more components. The main criterion when choosing a particular bur for work is an understanding of the processes occurring at the moment of direct contact of the rotating tool with the processed hard tooth tissues. And, of course, the endless variety of burs that now exists on the dental market does not at all add a clear understanding of the preparation mechanism. Today, burs are divided mainly according to the type of tips for which they are intended, according to the structure of the working surface (carbide, diamond, with rubber or carborundum working surface), according to manufacturing technology, and according to the size of the diamond chips (for diamond burs). But, unfortunately, there is currently no understandable, clearly structured and, importantly, convenient medical classification of hogs. Foreign manufacturing companies suggest that we, doctors, be guided in our work by the classification of burs according to the ISO standard. But the ISO standard was developed and used throughout the world as a standard for product manufacturers, and it is very difficult to imagine that a doctor in his everyday practice easily uses the 14-digit ISO boron code. And yet, despite the lack of a complete medical classification of hogs, it is possible to single out only one parameter by which the entire variety of hogs is divided as fundamental. This parameter, in our opinion, is the mechanism for removing hard tooth tissue. It is most logical to distinguish between burs with a cutting surface and burs with an abrasive (grinding) working surface. In the first case (cutting working surface), the removal of hard tissue occurs due to layer-by-layer cutting of tissue, in the second - due to gradual grinding from the surface. This approach to bur separation is supported by studies of prepared tooth surfaces, as well as significant differences in the tasks performed. The working surface of the abrasive bur consists of grains of artificial or natural diamond associated with the base. Such a surface is made either by pressing grain and a metal binder, or by galvanoplasty. Grinding grains perform effective work on excision of hard tooth tissues. The main operating characteristic of a diamond bur is its abrasiveness, determined by: the size of the working surface, the hardness of the diamond, the size of the crystals, the density of the grains, the adhesion strength of the grains in the bond, the orientation of the grain faces in relation to the working surface /1/. Taking into account the significant difference in the tasks performed, manufacturers produce technical and medical diamond burs in different ways (Fig. 1.).

rice. 1. Different immersion of grinding grain in technical and medical diamond tools. In medical diamond instruments, the abrasive crystals are less tightly bound to the base compared to technical instruments. This is explained by the need to ensure fast and efficient preparation with little (comparatively) effort. Let's imagine a situation where in a medical instrument the diamond grains are tightly connected to the base, as in the case of a technical instrument. In this form, using a bur in the mouth is simply impossible, since the pressure exerted on the bur must increase several times in order to effectively remove tissue, which is simply impossible in the oral cavity; or we will be forced to seriously increase the time of the grinding procedure in order to remove the required volumes. In addition, the grain of such an abrasive, having removed the hard tooth tissues several times, loses the sharpness of its edges, and the entire further grinding procedure turns into a process of simple friction, causing increased heating of the tooth tissues and increasing the risk of thermal damage to the pulp /2/. And let’s simulate a different situation: a technical diamond tool is made with a slight immersion of the diamond grain into the base. In this case, under loads that are applied to the bur for technical needs, the grinding grain will fly out of its seat in the first minutes or even seconds of work. The quite obvious need to “free up” as many edges of the grinding grain as possible in the medical bur has led to the fact that the medical diamond bur is manufactured with a slight immersion of the crystals, which reduces the service life of the bur, but increases the efficiency of work compared to a technical bur. The working surface of the tool, operating on the principle of “layer-by-layer cutting”, consists of edges directed in accordance with the axis of rotation of the bur - knives. The edges are made of hard metals or their alloys and have a certain sharpening of the cutting surfaces according to the axis of rotation of the boron. The knife blade effectively removes hard tooth tissue. The working properties of such a bur are determined by the hardness of the knife metal, the number of edges, the angle of rotation of the blade relative to the bur axis, the sharpness of the blade, and the pitch (distance) between the knives. The hardness and, accordingly, the time of effective operation are influenced by the selected preparation mode, the sharpness of the blades, and the strength characteristics of the metal. So, we divided the whole variety of hogs into two main groups. Let's try to consider how different these groups are and where their capabilities are applied. In the course of our professional activities, we deal with only two hard tooth tissues - enamel and dentin. Enamel is the densest tissue of the human body, having a clear architecture and direction, and dentin is a less dense tissue without a clearly defined architecture. Let's try using the existing separation burs to remove each tissue and see what happens. An abrasive tool, according to the principle of its operation, should grind both enamel and dentin equally effectively. This is true, but only up to a certain point. In (Fig. 2.) two diamond burs are shown.

rice. 2. Below is a new abrasive tool, and at the top is the same bur, but 5 minutes after grinding off the dentin.

Below is a new abrasive tool, and above is the same bur, but 5 minutes after grinding off the dentin. It is quite clearly visible that all the abrasive grains of the bur are hidden by a layer of spent dentin, and such a bur can hardly continue to work effectively. Let's consider a cutting tool using approximately the same scheme. The architectonics of human enamel is such that no matter what angle you and I place the bur at the surface of the enamel, we will still cut the enamel across the enamel prisms, just as a tree trunk is cut down with an ax. But the modern design of cutting tools assumes the presence of horizontal notches on the working blades of the bur (Fig. 3.).

rice. 3. The modern design of cutting tools assumes the presence of horizontal notches on the working blades of the bur.

And if we look closely, we will find an amazing similarity between the bur blade and the saw. And of course, with such a tool it is already possible to remove both enamel and dentin quite effectively. But is this really so? Photo 4 shows the cutting tool after removing tooth enamel, after 5 and 10 minutes, respectively. Chips on the knife blades are clearly visible, and blade teeth that have lost their sharpness are visible.

rice. 4. Cutting instrument after removing tooth enamel, after 5 and 10 minutes, respectively. The conclusion from these photographs suggests itself: convincing, effective and, importantly, quite long-lasting operation of a rotary instrument varies depending on the mechanism for removing hard dental tissues. That is: the abrasive tool must work on the enamel, and the cutting tool must remove tooth dentin. A rational approach to choosing a bur depending on the task at hand and knowledge of the main aspects of the effectiveness of tissue removal will ensure that you carry out the preparation quickly, and your patients will undoubtedly gain more comfort in the dental chair.

Dental instruments (burs) for cavity preparation

When preparing cavities located on the proximal surfaces of teeth, a variety of types of dental instruments and burs are used. For example, if it is necessary to open a cavity that appeared as a result of the development of caries on premolars or molars, then in this case spherical diamond burs are most often used. When it comes to treating destruction of hard tooth tissues located on the proximal surface or on the lateral edges, then in this case the right choice would be a cylindrical diamond bur with a round edge.

You should be very careful when choosing tools to eliminate secondary caries or restore an old tooth. For example, when it is necessary to form a bevel of a gingival step, a cone-shaped bur, which is distinguished by the presence of a safe or rounded tip, may be suitable for this purpose.

When a dentist needs to prepare the walls of a cavity located on the proximal surface, it is recommended to use spherical burs of various sizes made from hard metal alloys. At the same time, it is very important that such a tool works at medium speed. Indeed, when using high speeds at the time of preparation or opening of a carious cavity, the risk of damage or even partial destruction of the tooth enamel structure significantly increases.

To avoid this, the dentist performs so-called finishing - processing the edges of the enamel using fine-grained diamond burs at medium speed. In addition, sometimes in such cases you can use certain types of manual dental instruments, as well as oscillating files.

If necessary, removal of enamel located in the cervical area, which was deprived of support in the form of hard tooth tissue, can be done using special types of hand instruments, including such as an enamel knife. When using it, it is necessary to apply force, while the cutting part of such a knife must be located in the same plane with its handle.

This type of hand tool is used in cases where it becomes necessary to cut off the enamel located in the area of the side edges of the strip, as well as directly near the gums. In addition, the enamel knife is highly versatile, as it allows you to carry out the procedure of finishing the bottom of the cavity, as well as the gingival wall. This must be done by making scraping movements, when the cutting side of the tool is almost perpendicular to its handle.

Another effective and common tool used for cutting and finishing the enamel surface of a tooth is the Wedelitedt chisel. The main difference from a chisel with a straight shape is that the working part of such a tool is curved, while the cutting surface has a slight bevel.

Another common tool is the marginal gum trimmer. It is used in cases where the formation of the gingival wall of carious cavities of the second class is required, as well as when carrying out work on finishing the outer edges of such a hole. It must be remembered that the choice of tool is made by its color. Thus, a blue trimmer is used to treat distal cavities, and an orange trimmer is used for mesial cavities. The working part of such a trimmer has a curved shape, while its cutting side is located at a slight angle relative to the working part.

When a dentist prepares dentin on proximal surfaces, in this case he can use specialized Sonicsys Micro attachments. They belong to the category of micro-tools, which have diamond coating on only one side, and are also available in a wide variety of shapes and sizes. The use of such attachments makes it possible to carry out high-quality and quick treatment of a cavity located on the proximal surface (even when the teeth are very close to each other).

In addition, Sonicsys Micro tips can be of two types, namely for distal and medial surfaces. At the same time, the diamond coating applied to only one side of the nozzle allows you to protect nearby teeth from damage. If you use a tool with increased pressure, its operating speed will decrease due to the absorption of the generated vibrations.

By the way, if it is necessary to treat a cavity located in a hard-to-reach place, Sonicsys Angle attachments can be used. They are recommended for use in the presence of small carious cavities located under the contact point.

When modeling the gums or exposing the subgingival cavity, special Tissue Trimmers can be used. They are burs that were created from ceramic material and are also designed specifically for treating soft tissues of the oral cavity. The standard rotation speed of the nozzle of such a tool is about 350,000 rpm. In this case, boron is used without using a water cooling system.

Dimensions of bur shaft for different types of tips

| Tip type | Length of burr rod in mm | Rod diameter in mm | Shape of the rod |

| Straight | 44 | 2,35 | Have a smooth shaft |

| Angular | 17 22 27 | 2,35 | At the end of the rod they have a circular slot for fastening in the corner tip |

| Turbine | 20 | 1,6 | The rod is smooth. The end of the bur tail must be rounded (so as not to damage the fixing sleeve) |

The shape of the working part has many varieties, depending on the functional purpose of the tool ( Fig. 3 and Table 5

). The surface of the working part can be made of different materials (steel, corundum, diamond chips, etc.).

Table 5

Purpose of hogs

| Name of burs according to the shape of the working part | Purpose of hogs |

| Globular | Designed for opening and expanding the carious cavity, removing necrotic dentin, forming semicircular retention points on the bottom and walls of the cavity, expanding the mouths of root canals, opening the tooth cavity, excision of fissures |

| Fissure burs: – cylindrical; – cone-shaped (straight truncated); – reverse-cone-shaped (reverse-truncated) | For forming vertical walls, right angles, flat bottoms. To open and expand the cavity; creating diverging (when the bottom of the cavity is narrower than the inlet) cavity walls To form a flat bottom of the cavity, create “undercuts” of sharp corners, give the cavity a retention shape |

| Wheel-shaped | Creation of retention linear undercuts on the walls of the carious cavity (within dentin) |

| Pear-shaped (reverse-cone with a hemisphere at the end according to ISO) | Used where it is necessary to round corners and form slightly diverging walls |

Fig.3. Burs of various shapes: a) spherical; b) cone-shaped

(reverse cone); c) cylindrical; d) wheel-shaped.

Since 1986, the International Organization for Standardization (ISO) has specified the characteristics of dental rotating instruments in a 15-digit digital code. The code is divided into 4 parts (groups). Each group of numbers has a letter designation: A, BC, D, E.

Group A. Under the letter A, 3 numbers are combined (1,2,3), which carry information about the nature of the material from which the head (working part) of the tool is made.

Codes 310-350 are different grades of steel.

Regular steel burs are code 310.

Codes 330,340 indicate that steel was used with increased antioxidant properties (surgical cutters are often made from this material). Steel burs can effectively cut only dentin and only at low speeds (up to 3 thousand rpm),

since at high speeds (more than 10-12 thousand rpm) when preparing enamel, very high temperatures are created on the cutting edges of the bur, leading to their melting and complete loss of efficiency.

Code 500 confirms that the head and adjacent part of the neck are made of tungsten carbide (an alloy created in 1947 using powder metallurgy) encased in a matrix of cobalt and nickel; the head is welded to the rod (during operation this is the mechanically weak point of the bur). Burs, cutters, and finishers made from this material are usually called “carbide” or “high-speed.”

These tools have high cutting ability and a long service life.

They are universal and suitable for processing many materials, dental treatment and prosthetics ( these burs can effectively cut not only dentin, but also enamel, chromium-nickel steel, silver-palladium alloy, amalgam

).

Code 506 is a type of carbide tool coated with titanium nitride to improve cutting efficiency. Outwardly they look unusual, “golden”.

ISO 800 group number – diamond abrasive grain. The last digit of the code indicates the method of attaching the diamond grain to the metal of the head. The most common method used in the production of diamond tools is the galvanic bonding method - this type of bonding is designated by the number 6.

All diamond tools produced using this technology are designated by the first group of code - 806 (80 means that the material of the working part is diamond grain, and 6 is the galvanic method of bonding the grain to the tool body). Code 807 – denotes the joining of diamond grains by other methods, for example, “sintered diamond”.

The range of diamond burs is very large, so it is often difficult to choose the right tool.

The most important criteria when choosing diamond burs:

1. Material used for coating (natural or synthetic diamond).

It is preferable to use burs coated with natural diamond, since the cutting edges of synthetic diamond crystals dull during the processing of the material, while with natural diamond this process is extremely slow. The service life of burs coated with natural diamond is 2-3 times longer than that of burs with synthetic diamond.

2. Coating thickness.

Single-layer coated burs have low wear resistance. Burs with one and a half to two layers of coating are more durable and effective. Diamond burs produced in Switzerland deserve attention. These burs are manufactured by applying a thick layer of natural diamond chips to a steel core. An indicator of the condition of the bur is the “gold” coating of the working part (as long as the golden color of the head remains, the burs can be used).

3. Shape of the working part.

Preference should be given to burs with rounded edges.

4. Shank shape and diameter.

Most dental institutions use turbine handpieces, in which the bur is fixed by clamping it into a polyethylene sleeve. There are strict requirements for the diameter of the bur shank: if it is thicker, the bur is not inserted into the tip, if thinner, it is not fixed, so when purchasing burs, it is advisable to check their diameter using the tip. In addition, the end of the tail must be rounded (otherwise it will damage the retaining sleeve).

5. Price/quality ratio.

The price of boron does not always correspond to its quality. Most domestic burs are not inferior to the best foreign samples in this indicator. In addition to conventional diamond burs, there are “TDA” burs and “Black Diamond” burs on the dental market.

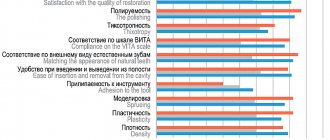

Rice. 4. Properties of boron “TDA” (according to data)

TDA burs have an original structure of intersecting spiral channels (Fig. 4). The advantages of such hogs:

– high processing speed and accuracy;

– effective cooling of tissues;

– immediate removal of decomposition products;

– durability.

Diamond burs of the “Black Diamond” type have a black bonding layer that sharply contrasts with the tooth tissue, which improves visibility and reduces visual fatigue for the dentist.

Recently, the interest of dentists in disposable diamond burs has increased. They differ from reusable ones in the thickness of the binding layer (Fig. 5).

Rice. 5. Thickness of the bonding layer for disposable diamond burs

In disposable burs, the diamond grains are recessed into the bonding layer by only 45%, while in reusable burs, 65% of the surface of the diamond grain is hidden.

Due to the fact that the diamond grain is more exposed, the abrasive ability of a disposable bur is higher and the cutting speed is higher. This allows you to reduce pressure on the bur, and, consequently, reduce overheating and damage to tooth tissue. At the same time, the diamond coating of these burs is unstable, and the bur must be thrown away after a single use. Disposable burs are supplied in sterile packaging. Disposable burs are approximately 4 times cheaper than reusable ones.

– one of the manufacturers of disposable diamond burs points out their following advantages:

1. Increased abrasive ability ensures maximum efficiency of the bur, and, therefore, significantly reduces the patient’s time at the appointment. High abrasive ability also prevents the bur from overheating and significantly reduces vibration.

2. There is no need to waste time on sterilizing instruments.

3. The use of disposable instruments reduces the risk of mutual infection between the doctor and the patient.

Codes 613-695 – various abrasive materials (corundum: 610-638 , silicone: 650-658 and so on). Abrasive instruments based on these materials in therapeutic dentistry are used mainly for processing fillings, as well as for polishing the surface of teeth after removing mineralized dental plaque.

Group BC (4, 5 and 6 digits). The second group of numbers reflects the characteristics of the shank of a rotating (rotary) tool (B – 4th and 5th digits) and the total length of the tool (C – 6th digit).

All rotary instruments, depending on their functional purpose, can have different lengths, diameters and types of connection between the shank and the tip.

There are 3 main types of connection between the shank and the tip, which have a corresponding ISO number in group 2 of the digital code. In addition, the designation of each type of connection in Latin letters has become widespread.

Rotary instruments used with straight handpieces are ISO numbered 104 (or letter designation - NTJ is the most common). Some companies are designated by the letters H, PM or HST. The diameter of the shank is 2.35 mm, and the length of the tool is in the range of 44-53 mm, depending on the length of the working part.

In contra-angle handpieces, where the rotation of the tool is carried out by transmitting driving energy directly from an electric or pneumatic motor through a system of gear connections, it is possible to use tools only with shanks that have a special slot at the end.

The tool shank diameter is 2.35 and is standard across all manufacturers. With a standard length of 22mm, the tools have a JSO 204 number , or letter code; the designation RA is most often used (sometimes in prospectuses you can find the designation W, AD, CA, WST). Depending on the functional purpose of the tool, its length may be different. With a tool length of 26mm, the ISO number will be 205, and the letter designation may be. RAL or RA SL. Some Swiss companies produce burs for contra-angle handpieces with lengths of 15, 22.6 and 28 mm. However, regardless of possible changes in the second and third digits of the ISO number, the first digit of this group will always be constant - 2.

It is this first digit of this group that indicates that the instrument can be used. used only when working with a contra-angle tip that holds the tool by means of a retainer that fits into the groove in the end part of the tool shank.

In turbine handpieces, rotary instruments are fixed due to friction (Friction Grip) without any technical devices. Therefore, the letters FG were chosen to designate this group of instruments. According to ISO, this group of instruments corresponds to the first digit 3 of a three-digit number. The shank diameter of all tools in this group is standard – 1.6 mm ± 0.01 mm.

The length of the instruments in this group may be different. The tool length of 16 mm corresponds to the ISO 313 number and letter designation FGM. To use them, you need a turbine handpiece with a special small head. The short shank makes it possible to work in hard-to-reach preparation areas and work in the child’s mouth.

The most common length of instruments in this group is 19 mm, according to ISO – 314 (FG). Long instruments, 21 mm are ISO numbered 315; extra long, 25 mm – number 316 and 30 mm – 317.

The end part of the tool shank for the turbine tip m.b. flat or rounded. In clinical practice, instruments with a rounded end are most convenient. They are easier to insert into the handpiece turbine and do not damage the retaining sleeve.

Burs from ISO-certified manufacturers typically have a color-coded ring on the shank indicating the grain size of the diamond chips on the working part. She might. made in the form of a groove or slight convexity on the body of the shank. Some companies (NTI) have raised markings for several purposes. One of them indicates the optimal depth of boron insertion into the handpiece turbine. Another purpose of the marking convex ring is to close the turbine channel and protect it from particles of processed materials and fabrics. Some difficulties may arise with fixing a bur with an average grain size of the working surface (M). Burs of this group do not have color markings on the shank.

Group D. The six digits of this group contain information about the shape of the working part (7,8,9 digits) and the type of cutting working part or the type of grain size of the abrasive material (10,11,12 digits) (Table 6).

For burs, cutters, and finishers, this is the structure of the cutting edge; for grinding tools, this is the size of the abrasive particles.

7,8,9 – the shape of the working surface of rotary instruments is one of their characteristics, which has the largest number of variations, due to the functional purpose of each specific instrument.

Different manufacturers offer in their catalogs from 20 to 50 modifications of the shapes of the working surfaces of tools.

Table 6

Basic forms of instruments

| Form | ISO code (7,8 and 9 digits) | ISO group number (10, 11, 12 digits) |

| Globular | 001-007 | 001 |

| Reverse cone | 010-039 | 010 |

| Wheel-shaped | 040-100 | 040 |

| Flame-shaped | 239-252 | 243 |

| Cylindrical | 107-158 | 107 |

| Pear-shaped | — | 237 |

| Discs | 320-392 | Etc. |

| Endodontic Instruments | C 417 |

Numbers 10, 11, 12 contain information about the type of cutting of the teeth on the surface of the working tool or the type of abrasive grain size. Each tool, depending on the number of teeth and their geometric location on the working surface of the tool, corresponds to a specific number. For example, a spherical bur with a standard cut of teeth, regardless of the diameter of the working part, corresponds to a number according to JSO 001 (a reverse and pear-shaped bur with the same cut of teeth will have a similar number according to JSO 001)

Cutters with standard toothing correspond to number 175

, and with a cross-shaped notch -

190

.

Finers – tools used for finishing the surfaces of metals and composites – usually have 8, 12, 16 and 30 cutting teeth:

a) 8 and 12 tooth tools are color coded red

on the shank and

code number according to JSO 071-072 ;

b) color marking of tools with 16 teeth - yellow and code number 041 ;

c) tools with 30 cutting teeth are marked white

on the shank and

the number of the fourth group of code 031 .

There are many types of cutting teeth. It is difficult to remember them right away. The skill of marking and reading it is developed in the process of work.

With the type of abrasive grain depending on the size of its particles, the situation is simpler. The following JSO designations are available (Table 7):

Table 7