- What is zirconium dioxide?

- Manufacturing and installation features

- Types of zirconium dioxide crowns

- What are the pros and cons

- Recommendations for choosing colors

- Which crowns are better?

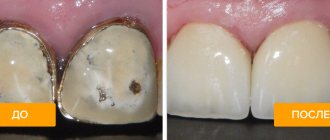

The prosthetic procedure involves the use of artificial crowns, which serve as a replacement for a real tooth. Prostheses made of zirconium are considered the most reliable and durable, and they also look more aesthetically pleasing than products made from metal ceramics. But which zirconium crowns are better, and how to choose them correctly? A properly selected prosthesis will guarantee long service life and a beautiful smile.

Zirconium dioxide bridges – what are they and what are their features?

Article navigation

- What kind of material

- Zirconium dioxide bridge

- Advantages

- Are there any disadvantages?

- Indications and contraindications

- Manufacturing stages

- Popular manufacturers

- Service life and guarantees

- Habituation and care

- Price

Question for a specialist

With the invention of new materials and technologies for their processing, dental prosthetics has made a big step forward. Today, orthopedists are increasingly offering patients zirconium bridges - as durable as metal and aesthetically pleasing as ceramics. In today’s article we will tell you all about the features of a zirconium dioxide dental bridge, for what indications it is used and for whom it is contraindicated, and also dwell on other popular questions on the topic.

How zirconium differs from other microprostheses

The fundamental differences between zirconium veneers and classic ceramic ones1 are as follows:

- manufacturing process: it is more complex, but at the same time precise, which makes it possible to achieve almost ideal positioning of microprostheses on the teeth. They fit tightly, food residues do not get clogged into microcracks, which means there is no risk of developing caries under dentures.

- Zirconium dioxide is a very durable material: microprostheses are thinner during processing (therefore, the enamel is ground down very little) and are very resistant to stress.

%akc72%

If we consider the differences from lumineers, then you need to know that these thinnest veneers are created using secret technologies in the CERINATE company. Production is carried out only in a laboratory located in the USA, and the exact composition of the material is also unknown. If a person wants lumineers, then the orthopedist will only prepare the teeth (grinding is almost never required here) and take impressions, which will be sent to the manufacturer by plane. Lumineers last longer than zirconium microprostheses.

What is this material and where is it mined?

Let's start with the fact that zirconium is a gray metal. And natural zirconium dioxide (dioxide, oxide) - badelleite, is also a gray substance. But it is successfully used as a raw material for many industries, medicine, incl. and dentistry. Natural zirconium dioxide is found in the mineral zircon (natural zirconium silicate) - it was first isolated back in 1789. Multi-level purification and high-tech processing of natural zirconium compounds makes it possible to obtain its dioxide with “ceramic” properties - white color and bioinertness (compatibility with the human body).

Only until December 25 South Korean implant Osstem - from 18,500 rubles.

Hurry up to sign up for a free consultation and lock in promotional prices.

Call now or request a call

Opening hours: 24 hours a day - seven days a week

You also need to know that zirconium dioxide has a high bending strength coefficient - about 1400 Megapascals (versus 950 MPa for the metal alloy of chromium and cobalt, for example), a compressive strength of up to 4700 MPa, and its melting point is above 2700 degrees Celsius . These characteristics classify the material as “metal-free ceramics” (this also includes aluminum oxide). That is, from such ceramics it is possible to make a one-piece prosthesis without using metal as a base - caps or bridge frame. This frame will be made specifically from zirconium oxide.

comparison table

Characteristics Zirconium dioxide Metal ceramics Metal-free ceramics

| Aesthetics | Limited. The milky white color is almost not corrected, so the teeth look unnatural. | Limited. Metal does not transmit light, so in order to achieve maximum naturalness, you have to apply a large layer of ceramics, and as a result, heavily prepare the tooth. | Maximum. Almost no different from the enamel of natural teeth. |

| Adaptation | It is absolutely hypoallergenic. Does not cause gum atrophy, fits tightly, protecting against the development of caries, and is suitable for bruxism. | Very often causes allergies. Black or bluish rims may form around metal-ceramic crowns as a result of metal oxidation. This reaction provokes the destruction of soft and bone tissues and spoils the appearance of the gums. | Does not cause allergies, but is not suitable for chewing teeth. With bruxism, a large number of missing units unevenly distributes the load on the gums. |

| Implantation | Excellent osseointegration. There is no effect of bone loss, protection from bacteria due to the tight connection of the crown to the gum. | There may be complications during wearing. In combination with titanium abutments, irritation and inflammation of the gums often occur. | Not used. |

| Price | From 17,000 rubles, on an implant – from 25,000 rubles. | From 7,500 rubles, on an implant – from 18,500 rubles. | From 20,000 rubles. |

As can be seen from the table, zirconium crowns, despite their rather high cost, combine versatility, reliability and aesthetics, and therefore are the best option for prosthetics and implantation.

Zirconium dioxide bridge – what is it, types

A zirconium dioxide dental bridge is a non-removable orthopedic structure that includes several crowns (0.5 mm thick) that is placed over abutment teeth or implants and restores missing teeth. Moreover, crowns are not created separately - they initially represent a single whole, i.e. bridge prosthesis. As a rule, in such a design there are no additional elements - acrylic gum and overlapping palate. But in exceptional cases, artificial gum can be built up along the edges of the crowns - when, for example, the patient has an uneven or unaesthetic natural gum level.

If we consider the types of zirconia bridges, we get the following classification:

- monolithic: made only from zirconium dioxide, without ceramic lining or painting,

- additionally colored zirconia bridges,

- classic or two-layer: zirconium dioxide frames, lined with ceramics to enhance aesthetics.

Advantages of metal-free ceramic bridges

Orthopedic dentists often recommend bridges made of zirconium dioxide to their patients, since this material gives the structures such positive qualities as:

- very high aesthetics and its long-term preservation (only with high-quality manufacturing): the material does not absorb dyes, less plaque settles on it than on tooth enamel,

- does not provoke “blueness” of the gums, like metal ceramics,

- biocompatibility, very low risk of allergies,

- the highest strength: several times higher than the strength of ceramics, and also stronger than some metal alloys,

- have a thinner layer of ceramics on top (compared to metal ceramics): because the metal is gray - under very thin ceramics it can be seen through,

- possibility of installation in any part of the row on natural teeth, as well as on dental implants,

- low thermal conductivity (compared to metal-ceramics): therefore, the supports under the prosthesis will not react so sharply to hot and cold food. But still, you shouldn’t get carried away with extremely hot and cold drinks / dishes, because... you can burn your gums and natural teeth,

- the supporting teeth do not need to be sharpened much,

- low risk of secondary caries and odor from under the crowns: from the inside, the structure fits very tightly to the supports, without gaps,

- very long service life: it is 20-25 years.

Life time

The strength of the material used determines the service life of the structure. Their average service life is 15 years , but with quality care and following doctors’ recommendations it can be much longer.

Despite confidence in the quality of their products, companies producing crowns of this type do not provide a warranty for operation for more than 5 years . But even this period is a good guarantee in case of unexpected deformation or breakdown of the structure.

Are there any disadvantages?

All the problems that patients encounter after installation - fracture of the prosthesis, chipped surfaces, injury to adjacent or opposite teeth (antagonists) - are often associated only with illiterate prosthetics or the use of low-quality material. If the orthopedic dentist is a professional in his field, if the laboratory follows all production rules and uses only high-quality products, then such problems are excluded.

As for chips, they occur on two-layer models - and it is the top ceramic layer that chips. This happens both due to a careless attitude towards restorations on the part of the patient, and due to the fact that, despite the strength of the frame being 1400 MPa, its adhesion strength to the top layer of ceramic is only 80-100 MPa. And the “older” the prosthesis, the weaker the connection between different materials becomes.

Some patients consider the high cost of zirconium dioxide bridges for teeth to be a disadvantage, because its final price is approximately 2 times higher than that of metal-ceramic. But the service life will be many times longer, plus you won’t have to spend money on re-prosthetics and preparation for it.

How veneers are attached - a step-by-step description of the process

Before fixing the veneer, a visual inspection is required and X-rays of the patient’s jaws are studied. Also, the preparatory stage involves the removal of plaque, supra- and subgingival deposits, replacement of old fillings, treatment of caries and inflammation, if any. After this, the veneering process can be represented in the following stages:

- preparation of enamel - a small thickness of living dental tissue is ground down so that after installing the plates, the anatomical parameters of the teeth are preserved so that they do not look more massive,

- formation of a rough surface to ensure reliable adhesion of the lining through the use of a heavy-duty adhesive composition,

- making impressions or creating a three-dimensional model of the patient’s dental system by scanning his oral cavity. After this, the obtained data enters a special program, where a prototype of the jaws is formed,

- during the production of permanent onlays, the patient is provided with temporary plastic plates, which not only mask aesthetic defects, but also provide protection for ground teeth from mechanical, chemical and temperature irritants,

- At the final appointment, the doctor fixes the veneers with a temporary adhesive, evaluates their quality and accuracy of shape, and then attaches the products with a permanent adhesive.

Installation of veneers

If you want to install zirconium onlays, choose monolithic products with a gradient. Models with ceramic cladding will be more massive and less aesthetically pleasing. In addition, they have an increased risk of chipping the cladding.

Indications and contraindications for installation

Zirconium dioxide bridges are good because they have a minimum of contraindications - they can be placed on almost all patients, both on the front and chewing teeth. The main indication for prosthetics with a zirconium dioxide bridge is the absence of 1-5 teeth in a row. But along the edges of the empty space, at least one healthy tooth or root should be preserved, which will serve as supports for the prosthesis. Also, an indication may be the presence of several adjacent teeth, the crowns of which are destroyed by 50% or more (and the patient does not want to place single artificial crowns).

Why might a dentist recommend a bridge made of a different material (for example, ceramic)? Often zirconia is opaque and unnaturally white. And if you put a bridge from it on 3 front teeth, then the smile will be lighter in one sector and darker in the other. Therefore, it is better to install a bridge of 4 or 6 crowns on the front teeth. And on the chewing ones you can put a prosthesis made of 3 crowns, because they don't fall into the smile zone.

Contraindications for installation are inflammation in the oral cavity, tooth mobility and bruxism - in this case, strong and involuntary clenching of the jaws will damage the enamel on the antagonist teeth.

Don't know what type of prosthetics to choose?

We will help in the selection, advise where to read more information and compare types of prosthetics.

Consultation with an orthopedic doctor in Moscow clinics is free! Call now or request a call

Working hours: from 9:00 to 21:00 - seven days a week

If the bridge is planned to be installed on implants1, then it can be of absolutely any length - even from 12-14 crowns, i.e. will restore all teeth in a row. But the patient may need gum plastic surgery so that the edges of the prosthesis seem to “hide” under the gum. Or you can supplement the prosthesis with small areas of acrylic gum, then they will not need plastic.

Read on the topic: what is a dental bridge on implants and why is it better than a classic one?

Manufacturing and installation stages

Before any type of prosthetics, patients must undergo diagnostics - visual, X-ray (optimally if it is a computed tomography), functional (best modern on digital devices). At these stages, contraindications are excluded, the shade of new teeth is selected, and bite parameters are assessed. If we look at it step by step, the manufacture and installation of prostheses looks like this:

- taking casts (impressions) from the jaws or undergoing a digital scan on an intraoral 3D scanner,

- creation of a virtual model of the prosthesis: modeling takes place in a specialized computer program. Here, a plaster model is first scanned (which was obtained on the basis of casts), or digital “casts” are used - the latter option speeds up the progress of work,

- milling a blank from a single block of material: model data is sent to a computerized robotic machine, which mills the frame blank. Interestingly, the blank will be 20% larger than the real one - why is this necessary, read on,

- sintering (sintering in a furnace): at high temperatures the material gains high strength, but shrinks by 20% of the volume,

- painting, applying a facing ceramic mass for sintering or pressing ceramics,

- processing the product at high temperature,

- Trying on temporary cement (for a few days maximum),

- final fixation: the finished product is attached to natural teeth and implants using a permanent cement composition. But they can be fixed onto implants with miniature screws, although even at the modeling stage it will be necessary to provide small holes in several crowns. Then these holes will be closed with a composite composition.

Zirconium dioxide is such a strong material that it is not possible to process it manually or use it for casting. Therefore, the only suitable processing method is milling (sawing, cutting) using CAD/CAM systems.

More about CAD/CAM methodology

The treatment involves recreating the patient's jaw using a three-dimensional visualization program - for this, in modern dental centers, specialists use a special intraoral scanner. The three-dimensional model created in the program repeats all the bends and features of the scanned area, thus allowing you to design the shape of the future product as accurately as possible, without the slightest inaccuracies or deviations. Before installation, you need to grind the tooth and decide whether it is possible to install a product with a ceramic coating or whether it is better to get by with a solid, more durable structure.

Recreating a patient's jaw using 3D imaging software

Next, a crown is created on a modern high-precision milling machine. The basis is a three-dimensional model of a monolithic structure or frame. The material is exposed to high temperatures, due to which it acquires additional strength. After applying the porcelain, re-firing is required.

This is interesting: Aligners for straightening teeth are the best alternative to braces for correcting a bite

Popular material manufacturers

Zirconium dioxide has been used for the manufacture of prosthetics for more than 20 years, but there are not many companies producing truly high-quality material. Let's consider the most famous brands that guarantee the highest quality:

- Prettau Anterior from Zirkonzahn (Italy): has a high degree of transparency, comes complete with liquids for coloring in natural shades in the laboratory,

- Katana Zirconia from Kuraray Noritake (Japan): comes in multi-layer discs with good clarity, easily dyed to any desired shade,

- IPS e.max ZirCAD MT Multi from Ivoclar Vivadent: polychromatic material has an almost natural gradation of transparency, but is only suitable for bridges with a length of 3 crowns,

- IPS e.max ZirCAD LT from Ivoclar Vivadent: a universal material that is used for bridges of 3 crowns or more and is also suitable for implant prostheses. Suitable for monolithic bridges and frameworks for ceramic veneering,

- Cercon xt / Cercon ht from Dentsply Sirona: This is a translucent zirconia stabilized with yttria, making it more durable,

- VITA YZ HT from Vita Zahnfabrik: characterized by good ability to transmit sunlight (almost like natural enamel). Easily painted in desired shades.

“I covered my front teeth with Prettau zirconium bridges. They look very good, for me it’s a perfect match in color)) And they even made the teeth a little longer. How they became when they were young, beautiful. I like everything, especially that the gums do not turn blue, and that they promise a very long service life. I hope that these bridges will last for a long time.”

Tatyana S., review from the website stomatology.rf

Habituation and care

The fewer teeth that need to be restored using a zirconium dioxide bridge, the faster the patient gets used to the dentures. You could even say that you won’t need to get used to it at all. But they also quickly get used to fairly extended orthopedic structures (in 2-3 days), because they exactly repeat the shape and size of the lost teeth - so a person feels comfortable with them. If the prosthesis contains small areas of artificial gum, then getting used to it may take no more than 1 week, sometimes a little longer.

Every six months after prosthetics, you must visit your doctor (orthopedic dentist) to identify or exclude dental diseases, damage to the structure or problems with its fastening. You will also often have to carry out comprehensive oral hygiene with a dental hygienist to remove plaque and tartar, which can cause complications.

As for care, the main thing is to regularly clean your teeth and dentures with a brush and paste. If the bridge is lined with ceramics, then it will not be possible to use a whitening paste with a high RDA index (the coating may be scratched). To prevent damage to the ceramic layer, loosening or peeling of the bridge, it is not recommended to eat very hard foods, chew nuts or seeds, chew gum, or toffees.

The cost of prosthetics and what it depends on

As already mentioned, the cost of zirconia bridge is quite high. Considering that the cost of 1 crown is 30-35 thousand rubles, the price of a bridge will be 90 thousand rubles and more. Prices are indicated on a turnkey basis, i.e. along with diagnostics, preparation of teeth, fabrication of the structure and its installation.

1Mish K. Orthopedic treatment based on dental implants, 2010.

Answers to frequently asked questions

Sometimes patients (who, for example, did not have prosthetics performed very competently) are interested in whether it is possible to increase the height of a zirconia bridge? Another popular question is whether it is possible to divide or saw the structure into several crowns and place each one separately? The answer to each of these questions is no! In any case, new prostheses will have to be made. Since it is impossible to “build up” part of the zirconium dioxide, it is fair to add that the height of the ceramic veneer can be slightly increased in individual cases. And the crowns formed after sawing the bridge will differ in shape and thickness from those that are made one at a time - and such a “sawed” restoration will not last long.

QUESTION Hello, tell me, I don’t have 1 molar on the side. Is it possible to install a zirconium bridge instead? Daniel

ANSWER Hello, Daniel. You can, but provided that at the edges of the “empty space” there are teeth that can become supports. That is, they must be healthy, or their roots must be healthy. To find out for sure whether a zirconium bridge is right for you, it is recommended to visit an orthopedic dentist and undergo an examination.