Digital dentistry is an ideal choice from a business perspective. Judge for yourself: a combination of high quality, patient convenience, low unit costs and optimized workflows. 3D printing, like the icing on the cake, perfectly complements the digital manufacturing process in the clinic. This market is growing rapidly, bringing the technology within reach of most manufacturers. But what technologies are relevant for dentistry? How do you compare printers based on quality, accuracy, and throughput? Why do some cost less than $5,000, while others cost $80,000 or more? Let's try to embrace the immensity and illuminate the Russian 3D printer market.

3D printing is based on additive manufacturing - the process of layer-by-layer joining of materials to create objects based on data from three-dimensional models. The following 3D printing technologies are common in dentistry today: stereolithography (SLA), selective laser melting and sintering (SLM and SLS), digital light processing (DLP) and jetting. Not long ago, another technology, Daylight Polymer Printing (DPP), appeared on the market - the polymer is cured in ordinary daylight, without the participation of a laser or projector. Each technology can provide the precision required for dental production, but quality may vary depending on the specific machine and system. There is plenty of information online about the technologies listed, so take some time to read about each one before making your final choice. Most importantly, remember that you need to evaluate specific equipment in terms of quality of parts, ease of use, reliability and cost.

Slash PLUS from UNIZa

What is the first thing a dentist needs from a 3D printer? Of course, in addition to high print quality. Of course, printing speed, which will allow you to work without hitches and significantly increase the number of patients. UNIZ Slash Plus combines both of these qualities. Thanks to a dual cooling system (the LCD screen and the backlight are cooled separately) and productivity up to 1000 cm3/hour, this is one of the fastest printers today.

Apart from this, there is no scaling issue for Slash Plus. Print resolution and precision are now independent of mask size, and the light is generated by the LED array. The printer has LCD stereolithography, which allows for a high print area and allows the production of models with a scale of 122 × 192 × 200 mm.

Uniz's work is based on the use of photopolymer resins that cure in LED light. Thanks to the uniform light source of Slash Plus, it provides high printing accuracy and productivity.

The printer has extremely simple and intuitive UNIZ software, which allows you to control the operation of several printers from one computer at the same time. A convenient interface will allow you to control its operation from your smartphone. It should be mentioned that the printer is easy to use, spill-proof, and easy to clean. Its body is made of reinforced steel and carbon fiber. But what is surprising is that, with all its high-tech functionality and capabilities, it has an absolutely affordable price.

- Printing technology: LCD;

- Printing speed: 200 cm³/hour;

- Printing area: 122 x 192 x 200 mm;

- Layer thickness: 10-300 microns;

- Dimensions: 35 × 40 × 53 cm.

WHERE CAN I BUY

What may be useful, but is not worth emphasizing

The standard marketing policy of any seller is to try to convince you to buy a product based not so much on direct value, but on features that sound and look good on paper, but do not greatly affect the quality of the product itself. A good example is the color of the delivery vehicle. If you do not take the opportunity to apply advertising images and colors from the brand book, the delivery vehicle can be of any color. But the seller may try to convince you to buy this particular car by appealing to its color.

Likewise, when choosing a 3D printer for a dental clinic, some criteria will not be as valuable as they sound.

Range of materials used

Modern LCD 3D printers mostly use ultraviolet light with a wavelength of 380nm-405nm to illuminate the photopolymer. The ability to use specific materials seems like a very useful quality, but in fact, you either know for sure that you will use such materials, or you will not use them. It is enough to understand what range of tasks a 3D printer will solve and choose accordingly. At the same time, it will be useful to be able to more conveniently use the selected materials, for example, a system of material profiles.

It is important that it is not economically feasible to expand the range of materials used unnecessarily.

Additional software - pros and cons

Software that helps you print. FormWare Phrozen Edition.

The entire process of creating printouts involves the use of several software products. And, if software that allows you to make printing easier or faster without losing quality is useful, then different programs for modeling or, for example, creating time-lapses of printing will never be used. The specialist models in the environment to which he is accustomed, and time-lapses are simply a beautiful feature.

Remote printing and control over it

When you imagine 3D printing, there are often assumptions that I pressed a button, came back an hour later, and everything is ready. It's actually not that automated. In principle, it is better to keep the machine under supervision at least during the start of printing. This means that remote printing will not be so popular. At the same time, I note that after the 3D printer operator gets used to working with a particular machine and knows most of its features, the ability to transfer files to the device remotely, or even remotely control the print, will be useful.

Remote control will be more beneficial to an experienced operator, although a beginner in 3D printing will gain experience quickly if desired.

FS121M-E from Farsoon

The peculiarity of this model is that FS121M-E has a narrow specialization in the production of products for dental use. The main difference with the FS121M-E is the reduction in final cost due to the use of an F-theta lens instead of a dynamic focusing system, mechanical features and limited access to material parameters, which are used primarily in materials research and development. The vacuum system for fixing the work table allows for the most efficient use of the entire construction area for the placement and production of products. Up to 170 crown models can be placed on one work table. Their printing time is 6 hours.

It is important to note that Farsoon equipment has an open architecture and can be used with materials from third-party manufacturers.

- Detailing: wall thickness 0.3 mm;

- Accuracy: no worse than 0.05 (up to 0.025-0.03) mm;

- Material: CoCrMoW;

- Printing technology: SLS, SLM;

- Print area: 120 x 120 x 100 mm;

- Layer thickness: 0.02 – 0.08 mm;

- Average consumption of inert gas (argon/nitrogen): 3 l/min;

- Dimensions: 100 x 78 x 170 cm.

WHERE CAN I BUY

Aligners

The production of aligners in 3D occurs according to the following algorithm:

- The specialist makes a cast of the patient’s jaw from plaster and scans it. Alternatively, an impression can be taken using two-part silicone.

- In the software, based on a scan of the impression, the dentition in different states is modeled in phases: from the crooked position of the teeth to a perfectly straight smile.

- The file is sent for printing. Using the printed modified models, the aligners are vacuum formed.

The doctor checks the quality of the print and hands the aligners to the patient.

What are the benefits of 3D printing in the production of aligners?

3D printing is more profitable than traditional aligner production for at least three reasons:

- This is more economical from a financial point of view.

- Treatment can begin the very next day after the jaw impression is scanned.

- If the aligner turns out to be defective or deteriorates during use, it can be replaced literally in one day and with minimal expense.

For the patient, all this creates additional psychological comfort.

What equipment and software is needed to make aligners?

The following programs are most in demand for the production of aligners:

- 3D Shape. Functional and easy-to-use software, the only drawback of which is the need for an annual renewal of the paid license.

- Maestro 3d Ortho Studio. The license for this program is purchased only once, and then additional modules can be purchased for the software. Those options that were present in the program initially will remain available even if the user does not purchase new modules.

- "Avantis". This is Russian software whose license does not include a module for outputting .STL files. You will have to pay extra for this module separately.

ATTENTION. All these programs belong to the CAD category, that is, autonomous design systems.

Here's what the 3D printed aligners look like:

Bracket systems

With the traditional approach, the orthodontist places braces on each tooth as he sees fit. But the computer can perform a more accurate calculation and suggest on which part of the tooth it is optimal to place the brace. Using 3D technology, a tray is first printed, on which the bracket system is then placed. This approach allows you to increase the effectiveness of treatment and reduce the duration of wearing braces.

ATTENTION. Braces are gradually becoming a thing of the past, as they are too conspicuous, and their glue deteriorates tooth enamel. In the future, they will likely be completely replaced by aligners.

Liquid Crystal DENTAL by Photocentric

Photocentric is actively working on creating a new generation of printers. In the new model, designed specifically for dental use, the manufacturer uses UV LCD printing technology instead of DPP. Thanks to this, in addition to high accuracy characteristics, the device provides the ability to use materials from third-party manufacturers of photopolymer resins for dentistry, including those certified in Russia. I must say that the result was worthy. Compared to previous versions, this model is faster and more productive: 42 dental models can be produced in 1 hour.

- Printing technology: UV LCD;

- Printing area: 293 x 165 x 250 mm;

- Printing speed: 42 models in 1 hour, 30 minutes for temporary crown platform.

WHERE CAN I BUY

3D printer in dentistry for the production of implants for prosthetics

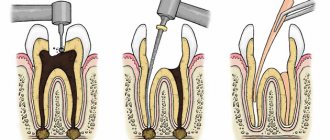

Today, surgical templates are successfully printed using 3D printers. They allow you to drill at exactly the right angle, ensure correct positioning of the implant and avoid complications. First, the patient comes to the doctor to take an impression and receive a referral for a CT scan. Implantation itself occurs in the second session.

Manufacturing of surgical templates

Templates must be made exclusively from solid transparent materials that can withstand high temperatures. They are usually modeled in the Implant Assistant program, which provides high-quality technical support in Russian.

Advantages of using surgical guides and main problems

When installing implants, an inexperienced doctor can harm the patient’s health if he accidentally:

- will drill at the wrong angle;

- will drill too deep or not deep enough;

- does not position the implant accurately.

In order for the bone tissue to recover after such an error, it sometimes takes up to 12 months to wait. If you make a template, the drilling will be done as accurately as possible. 3D printing can provide precision that is currently unattainable by any other cost-effective technology.

Dental models

Over 90% of models in dentistry today are made by hand. This is long, dirty, painstaking work that can never be compared to automated production in terms of accuracy.

Some components - for example, clasp dentures - can only be made by casting or 3D printing. It is impossible to use a cutter in this case, since the part is too thin. When casting, the probability of defects is too high; the product may turn out to be insufficiently elastic or strong. In 3D this risk is eliminated.

ATTENTION . Products printed on a 3D printer will always be homogeneous and monolithic. This is extremely important for crowns: if they turn out to be porous, the ceramics will begin to bounce off. A well-established printing process will avoid this undesirable consequence.

Liquid Crystal MAGNA by Photocentric

A new 3D printer model with a large print volume at an attractive price. A large desktop area allows the user to print a large number of models simultaneously without slowing down. For example, using the proprietary Photocentric MAGNA DENTAL WHITE photopolymer, you can create either 46 dental models in 2 hours or 105 dental models in 4 hours in one printing cycle.

- Printing technology: DPP;

- Printing area: 510 x 280 x 350 mm;

- Layer exposure time: from 14 sec;

- Layer thickness: 25-200 microns.

WHERE CAN I BUY

NextDent 5100 from 3D Systems

Using Figure 4™ technology provides high printing speed. A number of innovative solutions make it possible to achieve one of the best speeds and performance in its class, while the price of the device is acceptable for most clinics and laboratories.

Our range of dental materials and compatibility with leading dental software enable you to print trays, models (orthodontic/prosthetic), surgical guides, dentures, orthodontic splints, crowns and bridges with increased speed, accuracy and efficiency while maintaining low production costs. The printer is compatible with most intraoral and laboratory scanners. The display is touch-sensitive, but responds to touch with gloves.

- Printing technology: DLP;

- Print area: 124.8 x 70.2 x 196 mm;

- Maximum resolution: 1920 x 1080 pixels (Full HD);

- Printing speed: 20-30 minutes for printing models, 15-20 minutes for temporary crown platform;

- Dimensions: 42.6 x 48.9 x 97.1 cm.

WHERE CAN I BUY

Contraindications for prosthetics

In some cases, installation is impossible due to concomitant diseases. Local contraindications are:

- the presence of foci of inflammation in the oral cavity;

- insufficient hygiene;

- bleeding gums.

The list of general contraindications includes:

- pathologies limiting surgical intervention;

- allergic reactions to anesthetics;

- chronic diseases of the heart and blood vessels;

- diabetes;

- oncological diseases in the stage of decompensation;

- bleeding disorders;

- mental pathologies;

- exhaustion of the body after long-term drug or chemotherapy.

In addition, it is recommended to postpone prosthetics during pregnancy and lactation.

Duplicator 7 PLUS from Wanhao

Since the Wanhao Duplicator 7 was launched in 2022, it has created quite a stir in the DLP 3D printer market. The opportunity to purchase a DLP printer for $500 was a real sensation. Since then, hundreds of units have been sold worldwide. The new PLUS version costs a little more but offers some additional benefits. Thanks to such qualities as enhanced cooling and minimal error, the printer is a professional device for use in dentistry.

Comes fully assembled, just install the tray and add resin. You can use open source software. You don't need to buy anything other than the resin, sometimes the resin tank itself.

- Printing technology: DLP;

- Printing speed: 30 mm/h;

- Print area: 120.96 x 68.5 x 180 mm;

- Layer thickness: 35-100 microns;

- Dimensions: 35 x 35 x 52 cm.

WHERE CAN I BUY

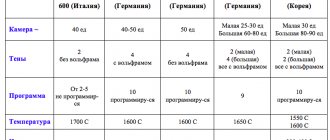

Post-processing and perfection of the prosthesis or model

Any “raw” workpiece requires post-processing, which guarantees an ideal surface and the desired physical properties. For these purposes, 2 additional devices are provided, which are often not included. The illumination chamber and ultrasonic cleaner stand out here. Typically post-processing includes the following steps:

1. Treatment with industrial alcohol. This allows any remaining resin to be removed.

2. An ultrasonic bath is used for additional processing. The cleaner does the job perfectly.

3. UV chamber is the last stage of exposure to the workpiece. It is used to increase strength, which is the most important performance property. The process takes no more than 15 minutes.

Today, the market offers special kits that speed up the process without sacrificing quality.

ZOBU from 3D Artel

The price for this model is more than acceptable, however, the print quality is excellent. The design of the guides ensures high positioning accuracy and reduces the likelihood of deviations. The printer is equipped with an LG diode matrix for better polymerization of the material. I must say that the model is very compact, given the rather large printing area.

A removable, almost opaque cap protects against accidental exposure. Control is carried out using a touch screen. This system is open.

- Printing technology: DLP;

- Print speed: 3 seconds/layer;

- Printing area: 115 x 65 x 155 mm;

- Dimensions: 22.5 x 22.5 x 41.5 cm.

WHERE CAN I BUY

Caring for your teeth after crowns are installed

Dentures are immune to tooth decay, but plaque can accumulate on them. With insufficient oral hygiene, it causes an unpleasant odor and the formation of tartar. As a result, healthy teeth may begin to decay.

Standard care for crowns boils down to preventative brushing of teeth twice a day and visiting the dentist once every six months. It is recommended to use pastes with a low abrasiveness coefficient, and remove food particles between the teeth using an irrigator or dental floss. It is also advisable to rinse your mouth after every meal.

Sudden temperature changes lead to the formation of microcracks in solid materials. To ensure that your crowns last as long as possible, you should avoid eating foods and drinks that are too hot or cold.

Hunter by FlashForge

Suitable for printing models, temporary crowns and surgical guides. The model gained its popularity among dentists due to the combination of good speed, high printing accuracy and low price. Professional FlashPrint software is compatible with most dental digital design software. The system is open and compatible with third generation polymers. The device does not require calibration, is equipped with a Full HD optical element and uses compensation technology, which makes it possible to obtain a model with smooth edges.

- Printing technology: DLP;

- Printing speed: up to 30 cm³/hour;

- Print area: 120 x 67.5 x 150 mm;

- Layer thickness: 35-100 microns;

- Dimensions: 36 x 31 x 56.5 cm.

WHERE CAN I BUY