Creating stamps

Requirements for LLC seals are not specified in the legislation of the Russian Federation, but many companies are trying to acquire them as an element of guarantee for their clients and partners. Enterprises also have various stamps in their arsenal.

Clear stamps first appeared 30-40 years ago, but their rubber counterparts have a much longer history. They appeared after the development of the chemical vulcanization process.

Read also: RAL Light ivory Tikkurila

Let us recall that vulcanization of rubber was discovered in 1839 by Charles Goodyear, and a patent for the invention was received in 1844.

Among those who can be considered the inventor of the first rubber stamp, three candidates are in the lead: Vizirell L.F. (Illinois, Knoxville), James Orton Woodruff (New York), or Henry S. Leland (Massachusetts, Knoxville). Lee).

One-step impression. Predictable excellent results

Yu. N. Ivlev

Ph.D., chief physician of the Author's Clinic of Aesthetic Dentistry (Novosibirsk)

The issue of obtaining a high-quality print has been actively discussed in recent years. The main topic of discussion, of course, is obtaining a predictable result, since the preparatory measures for obtaining a dental impression are very labor-intensive and repeating them in the event of a poor-quality impression can negatively affect the condition of the soft tissues.

In attempts to obtain a highly accurate copy, impression materials and methods for obtaining an impression were constantly improved. In our practice, for the last 8 years, we have been using exclusively a one-step technique for obtaining an impression, since, according to a number of authors, it is the most accurate (Fig. 1-7). However, the technique for carrying it out is more complex compared to the two-stage technique. The main problems that doctors encounter when taking a single-stage impression are the presence of pull-offs and poor presentation of the preparation margin. In our opinion, there are several important points to pay attention to when using the one-step impression technique.

Rice. 1. The situation before the start of treatment. Rice. 2. Adhesive preparation of the stumps of teeth 11 and 21 for an impression using the dental fluid composite material Filtek Bulk Fill (hereinafter referred to as the Filtek Bulk Fill material). Rice. 3. Filtek Bulk Fill composite material can be applied into the cavity in one portion up to 4 mm. Rice. 4. Preparation for ¾ veneers. Rice. 5. Impregum DuoSoft impression. Rice. 6. High accuracy in reproducing the preparation boundary. Rice. 7. Fixation of ¾ veneers.

1. Adequate work with soft tissues.

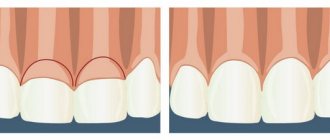

To visualize the preparation border, depending on the biotype of the gum, we use 3M ESPE Astringent Retraction Paste (Fig. or Ultrapak retraction threads (Ultradent). The method of using two threads (Fig. 9, 10) for retraction is presented below. The retraction procedure should performed very carefully using two instruments - a packer and a periodontal probe.

or Ultrapak retraction threads (Ultradent). The method of using two threads (Fig. 9, 10) for retraction is presented below. The retraction procedure should performed very carefully using two instruments - a packer and a periodontal probe.

Rice. 8. Using 3M ESPE Astringent Retraction Paste. Rice. 9. Retraction method using two threads. Rice. 10. Condition of soft tissues after removal of the second thread. The required vertical and horizontal displacement of the gingival margin has been achieved.

Technique for taking an impression using the two-thread technique:

1. Diagnostic probing, thread selection.

2. Insertion of the first, unimpregnated, 000 thread (Ultrpak, Ultradent).

3. If necessary, additional tooth preparation / ledge polishing.

4. Maintaining a second thread soaked in a buffer solution of aluminum chloride (no more than 10-15 minutes).

5. Removal of the second thread, irrigation and drying.

6. Applying a low-viscosity impression material to the preparation area, inflating it with a weak stream of air and applying a new portion to the dentition.

7. Placement of the impression tray with the base material.

2. Optimal state of material viscosity.

A-silicone impression compounds have good performance required to obtain a high-quality impression. But a significant drawback of these masses is the polar consistency of the base and corrective material, as a result of which it often happens that the more rigid base layer tears the corrective layer from the tooth stump, and significant delays and pores are formed. To solve this problem, several years ago we drew attention to the polyester dental impression material Impregum Penta Soft (hereinafter referred to as the polyester material Impregum Penta Soft), which was successfully used in fixed and removable prosthetics (Fig. 11-14).

Rice. 11. Upper jaw with installed implants. Rice. 12. Impression made from polyester material Impregum Penta Soft for the manufacture of a removable denture. Rice. 13. Temporary removable nylon prosthesis. Rice. 14. Temporary dentures in the oral cavity.

With the advent of the polyester dental impression material Impregum DuoSoft (hereinafter referred to as the polyester material Impregum DuoSoft), we have almost completely abandoned the use of A-silicone impression compounds, since the polyester impression material Impregum meets all the necessary requirements, namely:

- high accuracy of transfer of details of hard and soft tissues of the oral cavity;

- thixotropy, the absence of uncontrolled spreading of the mass during impression taking;

- hydrophilicity: the material perfectly reflects the relief of not only dry, but also wet surfaces;

- sufficient working time - 2 minutes 45 seconds;

- high final hardness of the impression, excellent resistance to deformation when removing the impression from the oral cavity;

- the viscosity of the base and corrective layers is as close as possible, which almost completely eliminates the occurrence of braces;

- delicate attitude towards soft tissues.

3. Correct insertion and positioning of the impression tray.

To take impressions from Impregum polyester materials, we use standard non-perforated trays with an internal retaining edge and custom-made trays for working with implants (open tray method). The introduction of the base layer into the oral cavity should be carried out parallel to the stumps of the prepared teeth. But this task is often impossible, especially if there are implants in the oral cavity, the impression copings of which can be at different angles. Under such conditions, it is almost impossible to obtain a high-quality print from polyvinylsiloxane. The viscosity of the polyester material Impregum DuoSoft allows some maneuvering of the impression tray without the formation of further pulls and pores (Fig. 15, 16).

Rice. 15. Upper jaw with installed implants. Rice. 16. Imprint made of polyester material Impregum DuoSoft. Ideal material for working with implants.

Another important point is the speed of insertion of the impression tray into the oral cavity. It should be low enough so that the impression material is evenly distributed on the surface of the teeth and soft tissues. Doctors often introduce a spoon with a base layer very quickly, fearing its rapid polymerization. Sufficient working time and mixing of Impregum DuoSoft polyester material in the Pentamix3 apparatus for automatic mixing of dental impression materials allows you to control the polymerization rate and obtain high-quality impressions of any complexity.

The excellent properties of the polyester material Impregum DuoSoft allow you to take uncompromisingly accurate impressions and create ceramic restorations with perfect marginal fit, and this material is also indispensable when working with implants.

Creation algorithm

To create a sample LLC seal, you need to complete several elements:

- identifying future customers;

- layout of the order, discussion of the layout with the client, selection of printing options, creation of a sketch, its clear elaboration;

- development of a sketch on film using a laser printer.

Numerous drivers, now freely available, make the print impression flawless.

Modern technologies help create models of different stamps that will become a distinctive feature of the company. After the preliminary sketch has been thought out, it is materialized, and a layout of the cliche is created into the finished equipment.

The importance of a functional impression in complete removable prosthetics

D. V. Serebrov

Ph.D., member of the Dental Association of Russia (StAR), orthopedic dentist, surgeon

Currently, many articles and other materials on prosthetic dentistry have been published on precision impressions. A separate list contains publications devoted to the working impression for complete removable prosthetics.

In the specialized literature, in numerous studies, the authors emphasize the importance of precision impressions for the manufacture of high-quality complete removable dentures, characterized by high aesthetic and functional characteristics. Nevertheless, many controversial issues related to the technique of obtaining an accurate impression with complete removable prosthetics served as the basis for writing this article.

With complete loss of teeth, functional disorders develop and atrophy of the facial skeleton and soft tissues covering it occurs. Due to these circumstances, prosthetics of toothless jaws is a method of restorative treatment that affects the delay of further atrophy.

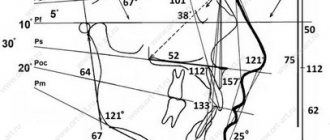

Despite the presence of many methods for determining the height of the bite, the central relationship of the jaws, and the dental manufacturing of the structure in the articulator, the working impression is still the basis of high-quality work. Accurate reproduction of the microrelief of the transitional fold and mucous membrane of the alveolar process without deformation will make it possible to produce a precision complete removable denture.

The procedure for obtaining a functional impression is divided into two stages. The first is fitting and shaping the edges of an individual impression tray. The second is to obtain a functional decompression impression.

The first thing to consider when making a custom tray is to isolate the undercuts that are often present on the alveolar ridges in the areas adjacent to the transition crease. This is due to the mushroom-shaped shape of the alveolar process. Most often, the alveolar process of the upper jaw has this shape. The lack of isolation of undercuts on plaster models during the manufacture of an individual impression tray leads to the inability to adequately apply the tray to the prosthetic bed, pain during insertion of the tray and an increase in working time during fitting.

The second is the choice of construction material for the manufacture of an individual impression tray. Today, the most common are cold-cured acrylates and light-curing plates.

When using cold-cured acrylates to make custom impression trays, be aware that these materials are characterized by a high degree of shrinkage. Therefore, in order to avoid thinning the walls of an individual spoon, it is necessary to apply the plastic mass in excess. After polymerization, it is necessary to process the spoon in such a way that the thickness of its walls is at least 2 and no more than 4 mm.

When using light-curing plates for the manufacture of individual trays, you must remember that after polymerization of the material, an inhibited layer remains on its surface, the adhesion of the impression material to which will be minimal. Therefore, after polymerization of the material, it is necessary to remove the inhibited layer from the surface of the individual tray.

The subsequent stage of fitting and shaping the edges of the individual tray depends on the impression material chosen by the doctor. The choice of technique and the impression mass itself is especially important in those clinical cases when we have a thick and loose submucosal layer.

In our clinic, we use Detaseal® function from DETAX to obtain a functional impression. This material has an ideal soft-plastic consistency with an extended curing phase in the oral cavity, which, combined with minimal shrinkage, allows the doctor to obtain a high-quality functional impression even in difficult clinical cases.

When using Detaseal®function we suggest the following procedure. An individual impression tray is fitted in the oral cavity in such a way that the edges of the individual tray do not reach the transitional fold by 1-1.5 mm. The spoon should not have primary stability. When applying the spoon to the underlying soft tissue, the patient should not feel painful or unpleasant areas.

After drying the spoon, it is necessary to treat its inner surface with adhesive for A-silicones or apply multiple perforations. The Detaseal®function mass is added to the individual tray in such a way that the entire inner surface of the tray is covered with impression mass, and the edges of the tray are simultaneously built up. After this, the tray with the Detaseal® function mass is introduced into the oral cavity, adapts to the soft tissues of the alveolar ridge with minimal pressure, the edges of the impression are formed by the soft tissues of the lips, cheeks and tongue. If necessary, subsequent correction of the impression is made using Detaseal® mono material from DETAX.

Clinical case

Patient D., born in 1933, with a diagnosis of third-degree chronic periodontitis of the teeth of the upper jaw, complicated by partial absence of teeth in the upper and lower jaws, mobile mucous ridge of the upper alveolar process, hypermobility of the soft tissues of the alveolar process of the upper jaw in the lateral sections.

Rice. 1. Initial situation. Rice. 2. Mobile teeth of the upper jaw were removed. Bone-forming material is introduced into the sockets of the extracted teeth. The holes are sutured. Rice. 3. Two weeks after the stitches are removed. Rice. 4. Two weeks after the stitches are removed. Rice. 5. Perforation of the surface of an individual impression tray. Rice. 6. Using the Detaseal® function material, a functional impression is obtained. Rice. 7. A functional impression is obtained using Detaseal® function material. Rice. 8. The impression was corrected using Detaseal® mono from DETAX. Rice. 9. The impression was corrected using Detaseal® mono from DETAX. Rice. 10. Using a facebow and a gnathometer, the centric relation was determined. Rice. 11. Using a facebow and a gnathometer, the centric relation was determined. Rice. 12. The impression with the 3D fork was sent to the dental laboratory. Rice. 13. Finished prosthesis. Rice. 14. Finished prosthesis. Rice. 15. Result.

Main

- Facsimile is a seal impression that reproduces a person’s signature.

- Facsimiles can be used by agreement of the parties or in accordance with the rules of document flow within the company.

- Facsimiles should not be used for documents that have serious financial or legal consequences.

- Facsimiles are ordered from organizations that make seals and stamps.

- Experts recommend ordering rubber cliches for facsimiles using automatic equipment.

- A facsimile signature differs from a handwritten signature in the details and presence of a raised mark on the paper.

Registering a business in Tinkoff

- We will register individual entrepreneurs and LLCs with one founder for free

- We will help you choose OKVED codes and send the documents to the tax office ourselves

- We will open an account automatically, service for the first two months is 0 ₽

View all conditions

Tags

Stamps Stamps for Printing for Relief Printing Stamps for Making for Making Stamps

seal of the organization case of use of articles and rights of documents person work to the manager gives a question form acts of registration contacts destruction near only deadlines text stamp to have the coat of arms of the state certification to make signs way authenticity is the size of contracts copy can rubber service should reproduce large other employees of the labor round Russian for example guest comments and instructions new temp of the federation its own kind ostanswersphonebusinessproductionexample