An individual tray is a device used at one stage of prosthetics. This design is needed to take impressions used in making the model and artificial crown. The impression obtained using a spoon repeats the anatomical features of the Patient’s bite and jaw and provides information for the production of an orthopedic device.

Dental individual impression trays are made in the form of a horseshoe-shaped product, which is filled with impression mass. The features of the tool ensure the accuracy of the resulting model, which is necessary for the correct manufacture of the future denture. This spoon is used once, which is necessary to ensure sterility conditions.

Indications

An individual tray in dentistry is used in the following cases:

- complete loss of teeth, partial edentia with the absence of a large sector of lost units;

- it is necessary to obtain high-precision impressions;

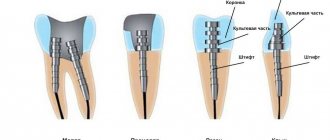

- production of crowns installed on implants of various types;

- with jaw deformities, which makes it difficult to use a standard type spoon.

Making a custom spoon

The initial impression of the jaws is made by an orthopedist using a standard tray. Based on the initial impression, the dental technician designs a custom tray. Its production requires the use of various techniques: wax, gypsum, using polystyrene sheets or plexiglass.

For an individual impression, plaster, thermoplastic material or impression elastic substance is used. The selection of mass will depend on the condition of the soft tissues of the patient’s jaw.

To make an individual wax spoon, you need to draw clear boundaries on a plaster model. After this, the heated plate of dental wax is tightly pressed with a plaster mold on both sides. Excess edges are removed with a hot spatula, along the previously measured border. Using a spirit lamp or gas torch, shape the edges of the spoon.

The wax tray does not make it possible to obtain an impression under pressure. For these purposes, a rigid plastic spoon is being developed.

Manufacturing methods and materials

The production of an individual spoon is carried out in an office or laboratory. Rubber, special types of polymers or wax are used as a base. This ensures the accuracy of the impression and makes the doctor’s work easier. In addition, such spoons are excellent for further use in the laboratory, creating a model for a future crown.

When working with Patients, positioners are used, that is, special limiters. When making a design for projection or anterior third, holes are first made in the material that do not participate in prosthetics. They form support points after the mass hardens. After the tray has hardened, it is crimped with wax to make impressions easier. At the same time, wings, sides, and a handle are made, making it easier to work with the spoon and remove it from the Patient’s mouth. After manufacturing, the finished model is placed in a box, where it undergoes a polymerization procedure.

Making a structure manually has a number of advantages:

- lack of high requirements for the qualifications of a dental technician;

- it is easy to work with materials and devices;

- manufacturing speed increases, which ensures comfort for the Patient;

- inaccuracies can be easily corrected;

- The cost of the device is low.

The technology has practically no disadvantages; a few disadvantages include the following:

- careful selection of material is required, as some options may cause allergic reactions;

- To polish and shape the finished individual spoon, you need a special set of cutters;

- Modeling handles and wings is not always convenient.

To create the installation, volumetric modeling and scanning of the oral cavity are used. This technique increases reliability, but in some cases the use of spoons is more appropriate. CAD technology, which can also be used in spoon manufacturing, eliminates process errors. It automatically reproduces anatomical features, eliminating the need for the technician to model the device manually.

After computer rendering, the model is transferred to the printer, where it is printed in full size. A complete 3D print can take several hours, as the image is divided into separate layers, each 20 microns thick. A laser is used for polymerization; each layer is pre-hardened, forming the required type of spoon with the specified parameters.

Comparison of open and closed spoon methods

Gray Radtz

Implantologists currently have three impression-taking methods to choose from: open tray, closed tray, and digital scanning. Each of these methods has its own advantages and disadvantages, and the choice is usually based on an assessment of the specific situation. Digital impression scanning currently has less than 10 percent market share in the United States, so we'll take a closer look at the remaining two methods. We will review when and where to use each method to maximize clinical success, create the most comfortable patient experience, and prevent possible failures.

The restorative part of the implantation is the culmination of many months of planning and painstaking work. The basis of the restoration is taking the final cast. Therefore, the doctor must take a responsible approach to choosing the method of taking an impression. Any one of them can produce the desired results, but in some cases one method may be preferred or even recommended for obtaining certain information.

When taking an impression using the open tray method, the impression cap retaining screw extends beyond the tray and must be unscrewed before removing the tray. When using the closed method, the impression cap is removed inside the impression, the impression is then removed, after which the cap is unscrewed and inserted back into the impression. The need to remove and re-insert the impression cap with the closed method inevitably leads to the possibility of an error, albeit small. Re-insertion and precise adjustment of the impression coping within the impression material requires close attention to detail. Any mistake at this stage will go through the entire implantation process and will certainly lead to an unsatisfactory result at the prosthetic stage.

So how can you determine in which case to use one or another method of taking an impression? In my practice, I use the open technique if one tooth needs to be restored and there are no factors preventing this. Sometimes when restoring a second molar, the patient cannot open his mouth wide enough to remove the retaining screw from the open tray. With a stronger restriction in mouth opening, the same situation arises when restoring the first molar. It is very important to ensure that the impression cap can be removed before choosing the open tray method.

When installing several implants, the choice of method must be approached even more critically. A contraindication for the closed method is taking an impression for several implants that are not parallel to each other (Fig. 1).

If you take an impression from such implants using the closed method, there is a high probability of blocking the impression in the mouth. Depending on the position and inclination of the implants, I sometimes use a combined approach with a closed impression coping on one implant and an open one on the other(s). In addition, when several teeth are implanted at the same time, the open method allows the doctor to connect the implants together, which in turn increases the stability and accuracy of the impression.

There is almost universal agreement among dental technicians that the open tray method is preferred due to its accuracy and stability. Our in-house technician Jeremy Johnson says, “Using an open technique increases the accuracy of the impression and greatly reduces the possibility of error.”

Let's talk about spoons

No discussion of impression-taking techniques would be complete without mentioning the choice of impression tray. Technicians almost always prefer full arch impressions.

“Full impressions provide greater stability of the model, as well as the accuracy, functional anatomy and esthetics of the final restoration,” says Johnson.

Next, you need to decide between a standard and an individual spoon. A standard tray can be used for one or two implants. If three or more implants are installed, a controversial situation arises. In this case, it would be a good idea to consult with a dental technician. When it comes to full implant prosthetics, the vast majority of doctors and technicians are inclined to use a custom tray.

Impression materials

Lastly, we will discuss the choice of impression material. As already mentioned, the best impressions for implantation are considered full impressions. As we know, taking an impression is a rather unpleasant procedure for many patients. When using an open technique, this process can become even more unpleasant because the impression remains in the mouth for additional time while the doctor removes the retaining screws.

When choosing an impression material, the following factors are taken into account: accuracy, mixing speed, tensile strength, hardening time and hydrophilicity.

I have found that Voco's V-Posil material combines all the necessary properties for taking impressions of implants. The material has excellent tensile strength, precision and hydrophilicity, and also shows acceptable working time. The material is heat sensitive and setting time is significantly reduced when the material is moved from room temperature to a warmer oral environment. When the material is placed in the mouth, hardening is actually accelerated to a “click hardening”. This ensures the stability of the impression and helps achieve the precision required for implantation.

Clinical case

This clinical case demonstrates open and closed methods of taking impressions for comparison purposes.

An implant was installed in the area of tooth 45 four months ago, and now it is time for prosthetics. The first impression was taken using a closed technique. In Fig. Figure 2 shows the imprint of the impression cap in the finished impression. The impression cap was then unscrewed from the implant and carefully placed into the impression. The impression was sent to the laboratory.

The open technique was then used. In Fig. Figure 3 is a model showing the position of the impression cap screwed into the implant.

It is clearly visible that the screw protrudes strongly beyond the occlusal plane, which makes it easy to unscrew it before removing the impression from the oral cavity. In Fig. Figure 4 shows what an impression taken using the open tray technique looks like.

Both impressions were sent to the laboratory and the models were cast. We asked the technicians to choose the most accurate impression, and they decided to work with an open impression. Rice. Figure 5 shows a working model of soft tissues with an implant analogue installed.

Using this model, a metal-ceramic crown with a screw fastening was made. Rice. 6. Trying on the finished crown in the oral cavity took no more than 10 minutes. The aesthetics and position of the crown turned out to be ideal.

Both open and closed impression techniques can provide the desired result if you strictly follow the technology, pay attention to detail and choose quality materials. However, none of these techniques can suit all clinical situations. Therefore, it is so important to evaluate each clinical case individually and make a choice based on this assessment. Mastering these two options allows you to consistently achieve excellent results for your patients.

about the author

Dr. Gray Radtz operates a private practice in Denver and is on the faculty of the University of Colorado School of Dental Medicine. Dr. Radz lectures in cosmetic and prosthetic dentistry and serves on the editorial boards of seven dental journals.

Installation steps

This tray is a jaw impression, as it is made based on the results of scanning and computer modeling. Therefore, the following steps are performed first:

- preliminary inspection, cleaning from plaque and stone;

- sanitation, treatment of oral diseases;

- removal of destroyed units, removal of damaged parts of the tooth;

- with complete edentia, exostoses are cut out from the jaw.

The working impression is made only after the individual dental tray is ready. To do this you need to complete the following steps:

- the impression mass is mixed and placed in a tray (the time of its use is limited, so the work is completed quickly);

- the design is inserted into the oral cavity, the fitting is careful;

- you need to hold the mass in the oral cavity for about four to six minutes, this forms an impression and fixes the bite;

- the edges are adjusted, then the unit is removed by the handle;

- this should be done in one motion so as not to lubricate the mass and cause deformation;

- the model is removed, washed in running water, and soaked in a special composition for further work.

You can start creating prosthetics thirty minutes after the prints are ready. In order for the resulting model to be accurate, the Patient is required to perform the following simple actions:

- removal of saliva, if swallowing is difficult, the doctor uses special instruments;

- The mouth should be opened wide and held in this position for a couple of minutes;

- During the hardening process, you need to lick your upper lip and touch the inner surface of your cheeks with your tongue.

Such simple steps make the fit complete, which has a positive effect on the quality of the resulting print.

Prices

Taking an impression with an individual tray is inexpensive and depends on the following parameters:

- methods and materials used;

- difficulty in taking an impression;

- features of the work.

Usually the prices are low and are included in the cost of implantation. The doctor will be able to name the cost after the initial examination, so you need to visit the clinic for a consultation, choosing methods for restoring the rad and determining prices.

About the clinic

Magenta Dental offers a wide range of services to restore functionality and aesthetics, including prosthetics. Patients are provided with the following benefits:

- services of dentists specializing in various fields of dentistry;

- an integrated approach, including diagnosis and preparation;

- comfortable reception conditions and attention to everyone;

- use of certified materials and special equipment;

- affordable prices, guarantee for work performed;

- no queues, possibility of making an appointment by phone.

To receive information about the preparation and prosthetics procedure or make an appointment, leave a request on the website. You can also call from 09.00 to 21.00 and consult with our managers on all treatment issues of concern.

Clinical examination

Before deciding to make a complete denture, you must undergo an examination and consultation with an orthopedic dentist. He examines the oral cavity and collects anamnesis. Diagnostics are carried out to identify the following problems:

- remains ;

- the presence of inflammatory processes, exostoses;

- the presence of other oral diseases

It is necessary to conduct a conversation with the patient to find out previous experience in wearing prostheses. If the answer is positive, it is necessary to find out whether it was comfortable to wear the prosthesis, whether psychological or physiological discomfort was observed.

Then the doctor needs to find out the extent of the disorder in the bone and soft tissue of the jaw; X-rays are used for this.

In rare cases, surgery is used to extract teeth growing in the wrong direction or to remove the alveolus of a tooth.

With the help of a clinical examination, it is possible to achieve the production of a perfectly fitting, high-quality prosthesis.

Custom tray fitting and functional impressions

After making an individual spoon, you need to store it. This procedure refers to the precise fitting of the original structure to the patient's jaw. To do this, the doctor uses the following tests:

- opening the mouth as wide as possible;

- swallowing;

- licking the upper and lower lips;

- the ability to stick out your tongue and reach the tip of your nose;

- trying to suck something;

- the ability to move the tongue along the cheeks and upper palate.

After each test, the location of the spoon is examined. If it rises, it is shortened in a strictly defined area.

Then move on to the next test. Testing is carried out until the initial structure fits snugly to the jaw during any movement. Only after this can you begin to obtain a functional impression.

It has certain requirements:

- clear imprints of jaw tissue and transitional folds;

- same thickness;

- absence of mucus , saliva, voids and pores;

- lack of gaps;

- presence of a rounded edge.

Only after achieving these indicators, trays with impressions can be transferred to the laboratory for the production of wax bases and a functional impression.

Final stages

After obtaining a clear fixation of the position of the jaws and the formation of a bite, you can begin making acrylic teeth. This is a critical stage, so the final product is obtained. In accordance with the wishes of the patient, a specific color of the teeth is selected, as well as their size and shape. They are installed on a wax layer, which will allow adjustment if the position and size of the model do not satisfy the patient 100 percent.

The doctor evaluates the following clinical picture:

- density of jaw closure;

- occlusal curves and centric relation of the jaws;

- the depth of overhang of the upper jaw over the lower jaw;

- density of jaw closure;

- aesthetic perception of an “artificial” smile;

- shade and shape of teeth;

- amplitude of jaw movement.

Rules for caring for removable dentures made of plastic

If these points are completely satisfactory to the patient and the doctor, the design will be transferred to the laboratory for final completion. The wax layer for attaching the teeth will be replaced with a plastic one. Before being handed over to the patient, the prosthesis is carefully ground and polished.

The final clinical stage is the delivery of the prosthesis. The doctor must examine the structure, treat it with antiseptic drugs and apply it to the patient’s jaws. The orthopedist conducts testing for tight fit, ensuring normal chewing and swallowing processes. It is important how comfortable the patient can talk and smile.

Even the final prosthesis can be adjusted. If the patient feels pain in the area where the structure is attached, the doctor recommends immediately stopping its use. The first meeting to adjust the product is scheduled the next day after the prosthesis is handed over. Next, the patient should visit the doctor at least once or twice a week. The period of getting used to the artificial structure lasts up to two months.

Prosthetics for completely edentulous patients is a very complex and problematic area in orthopedic dentistry. Thanks to Tony Johnson's latest technologies, it was possible to achieve reliable fixation of the structure and ideal occlusion. The main achievement is that a complete removable denture completely compensates for the absence of natural teeth, providing not only a functional component, but also an aesthetic one.

Making a working model, adjusting and fixing the central relationship between the jaws

This stage is described in great detail in Tony Johnson's manual, “Methods for making complete removable dentures.”

Occlusion is the correct closure of the teeth of the lower and upper jaw, on which chewing and the correct pronunciation of sounds depend.

The working model is an exact copy of the patient’s jaw. It not only completely restores the dentition, but also restores the correct contour of the patient’s face. For this purpose, special wax bite ridges are manufactured in the laboratory, which must meet the following requirements:

- ensure complete fit to the model;

- coincide with the previously outlined boundaries for prostheses;

- be of the same thickness;

- have a rounded edge.

After achieving this result, they begin to fix the central relationship of the jaws, namely the position of the lower jaw in relation to the upper.

Materials and types of diagnostic casts

Materials

To obtain a diagnostic impression, medical plaster and more modern plastic materials (thermoplastic and elastic masses) are used, which are able to acquire the shape of the dentition and maintain it.

All materials from which the impressions are made do not cause allergies. They are divided into several types:

- Hard (gypsum, dentol). They reproduce the texture of fabrics well, are easy to use, but are excessively rigid. Because of this, imprints of areas of the tooth located closer to the gum are not always successful.

- Elastic (silicone, alginate, etc.). To enhance the strength of the impression mass, special fillers are added to it. When heated, such an impression mass becomes softer and recreates the contours of tissues well. Disadvantage: elastic impressions are not suitable for long-term storage, unlike hard ones. For example, silicone impressions shrink within 3 hours after the impression. The model must be manufactured strictly within this period of time.

- Thermoplastic (gutta-percha, Kerr mass). The material becomes plastic when heated and hardens after cooling. Advantages of this type of casts:

- good separation from plaster during model making;

- Possibility of repeated administration into the oral cavity.

Types of casts

Compression . Made for the lower jaw. Purpose - to determine the distribution of load during chewing for the future prosthesis. Requires materials of high viscosity.

Unloading . They are used in the preparation of prosthetics for people whose activities are related to oral speech. When chewing, the load will be distributed unevenly.

Combined . With their help, dentures are made that evenly distribute the load both during eating and when talking.