ProRut is an excellent material for restoring tooth roots:

- simple application technique

- new tooth-colored formula

- biocompatibility

- water-based, good curing in humid environments

- absence of marginal permeability and prevention of bacterial invasion

- restoration of soft tissues without inflammation

Possessing unique properties and features, ProRut MTA has significant advantages over other materials for restoring root dentin:

Elimination of perforation of the bottom of the tooth cavity. Perforations as a result of clinical errors represent a communication between the dental cavity and periodontal tissues. ProRut MTA can seal perforations.

Elimination of root resorption. Internal root resorption as a result of an idiopathic condition manifests itself in the form of decay or destruction of root structures. The material can close defects during resorption.

- Retrograde filling of the root apex. Sealing the root apex is necessary in cases of endodontic treatment when a surgical (extraradicular) method is used. ProRuth MTA has excellent sealing ability and promotes periradicular healing as a retrograde filling material for apical root resection surgery.

- Protective pulp coating. In certain clinical situations, vital pulp treatment is indicated. Applying the material to the exposed pulp will in most cases result in healing and preservation of pulp vitality without additional treatment.

- Elimination of root perforations during endodontic treatment. Perforations as a result of clinical errors represent a communication between the root canal and periodontal tissues. ProRut MTA can close root wall perforations.

- Apexification. It is an excellent material for apexification because it seals the root tip, providing further sealing of the canal.

General overview

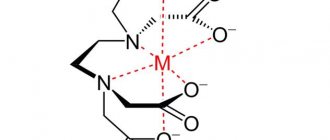

ProRoot MTA is a mineralized trioxide aggregate, crushed to the state of a fine hydrophilic powder.

In dentistry, this material is used as a protective cement during endodontic root canal treatment of teeth.

The peculiarity of the mass is its uniform solubility and hardening when interacting with liquid.

During the dissolution process, the powder first takes on the consistency of a homogeneous gel, which, when subsequently applied to the working area, hardens, creating a mechanical barrier that prevents damage and destruction of the walls of the root canals.

Filling the upper part of the tooth canal

The stages of filling include the following:

- Apply rubber dam, thoroughly clean the canal from sawdust and half-life products, using special tools to treat the space in the root and regularly spraying it with a liquid containing sodium hydrochloride.

- Carry out ultrasound treatment of the damaged cavity to the first class.

- Dry the area of the damaged tooth with special paper swabs and install it in the damaged area.

- Treat the channels in the nearest area against the detected defect.

- Prepare Prorut material in accordance with the instructions for use.

- Using a special dispenser-probe for placing Prorut from the supplied kit, apply Prorut to the area of the detected defect. Use a small plunger to compact the material into the damaged area, and also use paper and cotton swabs.

- Make sure that the drug has been placed correctly. An X-ray image will help you verify the correct placement of the Prorut. If it was not possible to create a strong barrier from the material, it must be washed with liquid from the damaged area and the application attempt must be repeated.

Operating principle and properties

The principle of action of the drug ProRut is the mechanical coating of the walls of the root canal, which leads to its restoration and prevents further destruction.

Thus, ProRoot is capable of sealing holes between periodontal tissues and the tooth cavity if it is necessary to treat dental perforations.

During the apexification procedure, the cementing material is able to isolate the apical part of the root, sealing the canal.

During the procedure for eliminating root resorption, ProRoot covers defects on the root surface , and during retrograde filling, it prevents moisture and bacteria from penetrating under the filling.

Additionally, ProRoot can be used to provide a protective pulp cap to restore tissue vitality.

Thus, the action of ProRut is multifunctional and can be used in various ways during treatment.

Let's find out together why a tooth hurts after root canal cleaning, and what can be done.

Come here to find out what you can do if a filling falls out of a tooth.

At this address https://www.vash-dentist.ru/lechenie/zubyi/plombyi/iz-chego-skladyivayutsya-tsenyi.html we will calculate how much it costs to change a filling in a tooth.

Purpose of the drug

Indications for use are:

- filling the upper part of the tooth root;

- restoration of the integrity of the canal openings in the root and the role of a blocking element;

- during the channel update in the system during procedural treatment;

- used for direct pulp capping.

There are no restrictions or contraindications for use.

It is important to know:

- Containers with the drug Pro Root, intended for restorative operations of the root system of teeth, are prescribed to be stored in a place inaccessible to moisture, securely packaged and away from sunlight.

- The product must be applied immediately after mixing it with water to avoid dehydration during shrinkage.

- This material should be used no higher than the root of the tooth and pulp, because due to its natural characteristics it can give such an unpleasant effect as loss of color of tooth enamel.

Advantages and disadvantages

The mass has a number of advantages that distinguish it from other cements:

- The material is sealed. This property makes it possible to exclude the proliferation of pathogenic bacteria and the penetration of liquids into the root canal, which is the key to successful restoration of dental root tissue.

Research shows that ProRut's hygiene indicators are much better than its direct analogues. - It practically does not cause rejection among patients, since only high-quality and safe elements are included in the composition.

- Able to harden even in humid conditions , which is especially important in dentistry, where drying the working cavity is not always possible.

The disadvantages of the material include a short working period after mixing (only 5 minutes) and the possibility of lack of hardening during installation.

However, the second drawback is offset by the fact that the material can be easily removed from the cavity without harm to the patient, and the procedure can be repeated again.

Restoration of resorption

The procedure includes the following steps:

- Using a rubber dam, finish the work in the cavity using burs at high speeds with constant wetting with water.

- Install the filling temporarily.

- After a week from the date of surgery, extract CaOH from the tooth and carry out the necessary treatment.

- Rinse the cavity and its surrounding area with a five percent solution of sodium hydrochloride. If bleeding occurs, it should be controlled using a cotton swab treated with a sterile solution.

- Prepare Pro Root as prescribed in the instructions.

- Taking a miniature applicator with a ball-shaped nozzle, apply a small amount of the mixture to the exposed area.

- Dry excess moisture in the work area using cotton wool.

- Mix.

- Using the supplied probe, apply the drug to the operated area.

- Use x-rays to verify correct placement.

- Fill the cavity and place a tampon on it.

- During the subsequent procedure, check the degree of hardening. If it has not completely hardened, clear the channel of it and apply it again.

Indications and contraindications

The paste can be used to solve the following clinical problems:

- Sealing may be indicated when performing a resection of the upper part of the root.

- Protection. If the pulp is viable, applying ProRoot material to it can speed up the resolution of the inflammatory process and maintain the functionality of the pulp chamber without additional intervention.

- Elimination of perforations of dental cavities during endodontic treatment.

- Apexification.

The product has no contraindications, except in cases of individual intolerance to the drug.

Despite its high cost, mineral trioxide aggregate (MTA) is becoming an increasingly popular material in the practice of endodontics and restorative dentistry. MTA consists of 80% ordinary Portland cement (OPC) with the addition of 20% bismuth trioxide, which provides radiopacity to the material for subsequent verification on X-ray images.

Despite the fact that the indications for the use of MTA in pathologies of primary teeth are obvious, the study of methods for its use is not unified across training programs at different dental faculties, which is to some extent due to its high cost. Thus, all information on the use and operation of MTA is reduced only to “instructions for use” and various clinical cases published in the literature. Although the described clinical studies of physicians using MTA can be used as additional educational material, they still do not provide all the necessary information regarding the step-by-step algorithm for practical manipulation of the material and the subsequent effect of these steps on the likelihood of clinical success. Since MTA is primarily Portland cement (OPC), it is advisable to review the literature on the use of OPC in the construction industry, and, having identified the key factors of the latter, draw logical parallels between it and aspects of clinical practice of application in dentistry. The clinical cases described below generally complement and detail the manufacturer's instructions for the use of MTA.

Interaction with water and mixing characteristics

Portland cement in the construction industry is most often used in combination with sand, gravel and water, when mixed to form regular concrete. Sand or gravel (referred to as aggregate) acts as a filler that provides additional strength to the final product, resulting in it being more resistant to heavy loads that must be taken into account, for example, in the construction of buildings, roads and bridges. When mixed, OPC reacts with water to form calcium silicate/hydroaluminates: (CaO)3(Al2O3)6H2O and (CaO)3(SiO2)24H2O), calcium hydroxide and water.

Finally hardened cement has a crystalline structure with voids containing water and calcium hydroxide. Despite its solid appearance, the material is not completely solidified, but rather exists in a specific associated liquid state, similar to the water contained in a wet sponge. During the reaction, the needle-shaped crystalline hydrates form a matrix that binds all the containing particles together and, in effect, transforms the original mixture of powder and liquid into a solid state, or colloidal gel. If water evaporates into the atmosphere during the solidification reaction, it significantly weakens the characteristics of the final reaction product. Therefore, loss of moisture during MTA curing is an extremely unfavorable condition that should be avoided.

Effect of acids on hardened material

When hardened cement comes into contact with acids, it loses its calcium hydroxide state as hydroxide ions begin to participate in acid-base reactions. This leads to the loss of hydration structures and thereby creates an etching effect on the surface. The procedure for one-time use of hydrochloric acid allows you to clean and etch the surface of both the unit and the matrix, however, contact with any other acids is contraindicated. In addition, exposure of MTA to strong acids causes etching of the material surface, which occurs due to the loss of calcium hydroxide from the structure of the hardened cement, as hydroxyl ions begin to react with the acid, which, as a consequence, leads to the dissolution of calcium silicate hydrates. Fluids from the environment when in contact with cement can renew lost calcium hydroxide or hydrates depending on the ions present in these fluids.

Presence of acids during mixing

In the construction industry, acidified water is never used in the concrete mixing process. This component leads to the formation of intermediate compounds that slow down the hydration of cement and limit the formation of calcium hydroxide. In addition, acids decompose both the structures of calcium silicate hydrates and calcium hydroxides. In the presence of acids, the compounds that form during solidification become more susceptible to dissolution, and this disrupts the formation of a network of intertwined crystals and also leads to their multiple leaching from the structure of the material. Even before pouring concrete on acidic soil, a process of so-called chemical stabilization or soil conditioning is carried out by first mixing the soil with an alkaline material (calcium oxide or hydroxide) until a neutral pH level is reached, and only then is cement laid.

From a dental point of view, “acid soil” includes deep caries (with the presence of organic acids in dentin), large numbers of bacteria, for example, in contaminated root canals, together with their acidic waste products and metabolites, as well as inflammation, for example, of periapical tissues. An acidic pH level can be found at the site of necrosis and inflammation.

As in construction, the presence of acids at the site where MTA is used negatively affects the hardening reaction of the cement. When the pH level of the medium decreases from 7.4 to 4.4, the probability of microleakage in the areas of the MTA edge contact increases significantly, and the strength of its adhesion to tissues, on the contrary, noticeably decreases. The action of an acidic environment also negatively affects the microhardness of hardened MTA, reducing its performance, and the microstructure of the material’s crystals changes from strict cubic and needle-shaped forms to an erosive-defective cubic form of the crystalline network. Therefore, the pH level must be stabilized and approach physiological normal values even before applying MTA. For example, filling the root canal of an abscessed tooth with calcium hydroxide for 1 to 2 weeks before placing MTA significantly improves the properties of the set cement. In addition, during apexogenesis of vital teeth, periodic treatment of the roots with calcium hydroxide can not only stimulate reparative processes at the apex of the tooth, but also help disinfect the canal.

It is believed that pre-treatment of the channel with calcium hydroxide may adversely affect the properties of MTA used as a sealer. This is likely due to the difficulty of completely removing residual calcium paste, which may act as a barrier to the adaptation of MTA to the root canal walls and also participate in the curing reaction of MTA. However, this view is contrary to the literature in the construction industry, which, on the contrary, recommends the use of calcium hydroxide to condition acidic soil. However, calcium hydroxide materials used in dentistry may contain various additives, such as methylcellulose and carboxymethylcellulose, which are known to slow down the curing process of Portland cement. Therefore, if calcium hydroxide pastes are still used, then to ensure quality, abundant irrigation and rinsing of the material should be carried out so that residual cellulose thickener does not in any way inhibit the MTA curing process. Accordingly, acid irrigants, pickling solutions and conditioners must also be properly washed out before applying MTA. Sodium hypochlorite (NaOCl) solutions, which have pH values above 11, will neutralize any remaining acids during root canal irrigation. As discussed earlier, the presence of acids can affect the hydration process of MTA, resulting in the formation of new compounds within its matrix structure that act as inhibitors of the chemical reaction. NaOCl, reacting with bismuth oxide, turns the yellow X-ray contrast powder into dark brown. To avoid darkening of the MTA due to the use of NaOCl, the prepared area should be rinsed copiously with saline. Given the darkening effect of the material, Belobrov and Parashos do not recommend the use of white MTA in the aesthetic zone, and in case of pulpotomy due to traumatic pulp exposure, use only calcium hydroxide.

Interaction with EDTA

Some commonly used irrigation solutions are not acidic (for example, disodium edetate has a pH value of 7.0-7.4, and tetrasodium ethylenediaminetetraacetic acid has a pH value of up to 11.3). The problem with ethylenediaminetetraacetic acid (EDTA) is not primarily its pH level, but the chelation effect that occurs. EDTA has 6 potential zones for binding positively charged ions, such as metal ions. Calcium ions, in turn, are important reagents in the hardening of Portland cement and MTA. If an EDTA solution is used to remove the smear layer during endodontic treatment and is not washed away properly, the residual EDTA will chelate calcium ions, thereby interfering with the precipitation of hydration products during the setting reaction. This explains the results of a study by Lee and colleagues, who observed that MTA placed in an EDTA solution loses its crystalline structure as the Ca/Si molar ratio drops. In addition, MTA treated with an EDTA solution has reduced microhardness and is less biocompatible, due to reduced fibroblast adhesion, compared to MTA that was not treated with EDTA.

Interaction with phosphoric acid

It follows from the above that phosphoric acid used to etch the prepared surface must be thoroughly washed off before installing the MTA. This recommendation should be especially taken into account in deep cavities or when cleaning pulp, which also contains organic acids of bacterial origin. Even in small quantities, phosphoric acid affects the curing reaction of MTA, reducing the microhardness of the material. Therefore, the etching agent should always be thoroughly flushed with water from the walls of the prepared cavity before inserting the MTA. Additionally, the MTA can be coated with glass ionomer cement (GIC) as a final step before etching the marginal region of the cavity. In most cases, the easiest way to limit the effects of etching solutions and EDTA is to irrigate and flush the problem area with plenty of water before applying MTA.

Substance contamination

The general principle of construction is simple: the higher the level of chemical impurities in the solution, the more likely it is that one or more of them will interfere with the hardening reaction of the cement, resulting in a decrease in its compressive strength. When MTA comes into contact with blood, its physical properties deteriorate: compressive strength and microhardness decrease, and tensile strength also decreases. In addition, in the presence of blood serum, the MTA hardening process is disrupted due to changes in the morphology of the contacting surface and a decrease in the level of microhardness, which, in general, slows down the reaction time. Although MTA's ability to cure in wet or blood-contaminated environments is a proprietary characteristic, it is desirable to minimize the possibility of any tissue fluids or blood coming into contact with MTA during application. This is especially important to consider in the area of cement edge contacts, where the possibility of microleakage is quite high, which can deteriorate the physical properties of the material. Dental practitioners must minimize the possibility of hemorrhagic contamination by all means possible, as excessive blood will not only impair visual control, but may also affect the curing quality of the final product.

MTA Liquid Component Variations

Various additives and impurities in the water when mixing concrete are already known to affect the curing reaction and the quality of the final product. Sodium chloride (as a component of saline solution) and many other inorganic and organic compounds are likely to slow down the curing process due to the formation of reaction by-products. Manufacturer's instructions for using MTA usually recommend using sterile or distilled water to mix with MTA powder. To provide passive quality control and clinician convenience, distilled water is often included in the same kit with MTA powder. Although MTA powder will harden when mixed with local anesthetic solutions, the reaction will be slower and the hardened material will have a lower level of compressive strength. When mixed with a NaOCl solution, MTA cures faster than when mixed with distilled water, but the compressive strength also has to be sacrificed. However, in situations where the cement is outside the immediate load area, this problem is not significant. In many cases, the benefit of an accelerated setting reaction, which is a reduced risk of potential for movement or separation of the restoration, must be justified in light of the reduced physical properties of the material. When using chlorhexidine gluconate as an alternative to sterile mixing water, there is no question of choice because this agent completely inhibits the MTA setting reaction.

Cement curing

The reaction of Portland cement with water is dynamic, so contact between the material and water must be maintained throughout the curing process of the material to ensure optimal structure and strength of the final product. If water evaporates, the strength of the cement is lost. In construction, there are even a number of techniques for minimizing water loss during the curing process, among which a certain place is occupied by the wet curing technique (pouring cement with water to compensate for evaporated liquid) and the membrane curing technique (coating cement with waterproof membranes to prevent evaporation). In clinical practice, the wet cure technique involves placing a damp cotton ball on the surface of the MTA while it cures. However, if the cotton ball is too dry (or at least drier than the cement surface), water will move in the opposite direction, from the cement into the cotton wool, thus weakening the MTA. If the cotton ball is too wet or was placed too early, this will also deteriorate the properties of the cement. The use of cotton balls delays the completion of the clinical procedure and may compromise the quality of the MTA restoration.

Based on the principles of membrane adhesion, in a clinical setting, MTA can be covered with GIC or a GIC liner modified with a composite. This procedure ensures the stability of the material, both in terms of water loss and in terms of its excessive absorption, and the clinician, in turn, can proceed to the final restoration of the tooth or obturation of the canals. This concept was tested using white ProRoot MTA (Dentsply, Johnson City, USA), which has an initial setting time of 45 minutes. GIC placed on top of MTA provides, after 45 minutes, bond strength to dentin similar to that of GIC after waiting 72 hours for MTA to fully cure. Therefore, there is simply no apparent advantage to leaving the MTA for several days to fully harden compared to restoring the tooth in one visit. However, there are not yet any well-founded studies that can evaluate the impact of coating MTA with GIC less than 45 minutes after its application. An alternative to GIC for MTA coating is the use of self-etch adhesives as a waterproof layer. In one study, a bonding agent was applied to the surface of the MTA 10 minutes after installation. As it turned out later, this approach did not affect either the Vickers microhardness of MTA or the bond with the adhesive agent compared to waiting 1 or 7 days after installing the cement itself. Again, this study only supports the postulate that it is possible to restore a tooth with composite cement with underlying MTA placement in a single visit.

MTA storage

Portland cement powder and MTA powder are highly hygroscopic, and when interacting with atmospheric air, they will absorb moisture from it, which will initiate the hydration process. Portland cement can be packaged in sealed bags and containers of appropriate size, but the issue of MTA packaging remains unresolved as some products are sold in reusable bottles. Recent studies have shown that opening a sealed container changes the particle size of the remaining MTA, which subsequently inhibits the curing process and reduces material quality. Disposable packaging in this case is the ideal solution. Alternatively, sealed containers can also reduce structural changes in the material during storage. The rate of hardening reaction of Portland cement decreases under low temperature conditions. Additionally, MTA stored in a refrigerator exhibits a significant decrease in surface hardness, greater porosity, and increased levels of microleakage, so storing MTA in such conditions should be avoided.

conclusions

This analysis of some of the characteristics of MTA provides a more accurate understanding of the material and its clinical use in dentistry.

Authors: William N. Ha, BDSc, GCResComm; Bill Kahler, DClinDent, PhD; Laurence J. Walsh, PhD, DDSc.

Kneading rules

Kneading does not cause any particular difficulties for a specialist, however, it requires a certain care and accuracy when performing.

To prepare the paste, you need to perform the following manipulations:

- Open the package of powder and pour it into a mixing container.

- Open the bottle of mixing liquid from the ProRoot kit and squeeze it out next to the powder mass.

- Using a mixing tool, carefully mix the liquid fraction with the powder for one minute.

- The resulting composition should have a uniform consistency and all its particles should be moistened.

- If necessary, add liquid from an additional ampoule or 2 drops of distilled water to the resulting mass.

It is recommended to stir the composition gradually and thoroughly, ensuring the uniform distribution of the liquid in the mass.

Then the cement will be pliable to work with and will harden evenly after application.

How to mix the material?

According to the instructions for use, mixing Prorut MTA consists of the following steps:

- open the container with the drug and transfer it to the surface for subsequent mixing;

- carefully open the container with the hardening liquid and place its contents next to the powder;

- carefully carry out the process of mixing the liquid component with the powder, use the mixing stick from the kit;

- Mix the two components for about sixty seconds to ensure mixing of the components and reliable moistening of the particles.

Hardening of Prorut differs from the similar process of other cementitious preparations. Careful and delicate mixing of the components of the product will make the material more convenient and manageable to use.

If the need arises, the Prorut MTA kit contains an additional capsule; you can add one or two drops to bring the drug to the desired consistency. You can also use distilled water. The remaining liquid must be disposed of.

Features of application

Let's consider the main features of the product:

- The cementing mass is prepared in full compliance with the instructions in the instructions. Using a probe supplied with the powder, ProRoot is placed into the defect area and then compacted using special tools.

- Verification of adequacy of material placement using radiographs. If the position is incorrect, the material should be washed and reinstalled.

- After installing the mass into the prepared canals, a damp cotton swab is placed, after which the canal is sealed with a temporary filling for a period of 4 hours or until the next appointment.

- On the second visit, the dentist uses the rubber dam and examines the installed material, checking it for hardness. If the material has not hardened well, it should be washed out of the cavity and installation repeated.

In this case, the product remains in the root canals, like a layer of permanent filling, sealing them and protecting them from negative external influences.

The use of the product significantly increases the chances of restoring the problematic element of the jaw arch and extends the life of the filling mass.

Main characteristics of cement fillings, reviews from dentists and patients.

This publication contains all the most important information about the technique of unfilling tooth canals.

Here https://www.vash-dentist.ru/lechenie/zubyi/plombyi/obturatsiya-kornevyih-kanalov.html read about the indications for obturation of the root canals of teeth.

Use of MTA in general dental practice

Modern endodontics derives many benefits from the use of magnification, and especially the operating microscope. However, as a recognized expert in the field, I know that many general dentists do not have the luxury of this sophisticated technology. But dental telescopic lenses are available (photo 3), the price of which will suit all practicing dentists. Their ability to increase by 2-3 times is sufficient to perform various numerous procedures for the use of MTA cement in the root canals of teeth. The following examples illustrate techniques using MTA cement that can be implemented in general dental practice with minimal magnification.

Useful tips

The composition hardens slightly longer than other cements. This feature should be taken into account when carrying out work. Careful mixing of the powder makes the material more convenient to use.

It is important to follow the recommendations for the amount of liquid when mixing , because... its insufficient or excessive amount can affect the strength of the mixture after hardening, and, therefore, lead to a significant decrease in the quality of the procedure.

The prepared mass hardens within 3 hours after mixing, however, the working time is limited to only 5 minutes.

If a specialist needs a longer period of time to work , then the mixed material can be covered with sterile gauze soaked in distillate to prevent the evaporation of moisture from it.

Instructions for mixing ProRut tooth root restoration material

Caution: ProRoot MTI does not cure as quickly as other cements. Careful mixing will make the material more flexible to use.

- Open the packet of ProRuth MTA material and place the material on the mixing pad.

- Tear off the tip of the microdose ampoule containing ProRut liquid and squeeze the contents onto a notepad next to the powder.

- Gradually mix the liquid into the cement using a ProRut MT-A mixing stick. Mix the material with the liquid for approximately 1 minute to ensure that all powder particles are moistened.

- If necessary (a spare ampoule is included or you can use distilled water), you can add 1-2 drops to mix the material to a creamy consistency. Discard any remaining liquid.

Note:

- Too little or too much liquid can reduce the strength of the cured material.

- ProRut MTA will harden within 4 hours, but working time is limited to 5 minutes. In case you need more working time, cover the mixed material with damp gauze to prevent evaporation.

Quantity:

5 x 1g. + 6 x 0.35g.

Nuances of use

Despite the existence of general principles of technology for using the ProRut material, each individual clinical case requires a special approach to the procedure.

Let's consider the main nuances of work when performing various tasks.

Perforation restoration

When performing a perforation repair procedure, it is important to ensure that the installed material is positioned adequately and that it hardens after installation.

During treatment, several control images using x-rays may be required, as well as reinstallation of poorly “adhered” material.

A detailed description of the procedure for restoring perforation can be found in the article above.

Pulp capping

There are the following features of the pulp capping procedure:

- A light-curing material is applied on top of the applied ProRut material, which is illuminated in accordance with the technology proposed by the manufacturer.

- Dentin cavities are etched for 15 seconds using phosphoric acid. After pickling, everything is thoroughly washed.

- Then, everything is dried so that the dentin remains slightly damp, but not excessively. An adhesive is applied to the dental tissue and illuminated in accordance with the technology.

- The procedure ends with the application of a composite material.

After the procedure is completed, the patient is scheduled for another appointment, during which the vitality of the pulp is assessed.

Restoration of the root apex

Filling the apical part of the root is performed using the following technology:

- The specialist opens access. Then the cavity is prepared using an ultrasonic instrument.

- The surgical area is isolated with a rubber dam. The root canals are dried. If bleeding occurs, stop it with a sealant sponge.

- ProRoot is mixed and applied to the defect area using the supplied probe. After application, the material must be compacted.

- Excess cementing gel is removed from the root surface using a moistened gauze cloth.

- The adequacy of the placement of the material is confirmed by taking an x-ray.

Thus, the ProRoot installation procedure does not require additional special tools, and if errors occur in the installation, everything can be corrected without harm to the patient.

The composition remains at the apex of the root, playing the role of one of the components of a permanent filling, protecting the root from negative influences.

Root apexification

Root apexification is performed using a technology similar to the procedure for restoring perforation.

The procedure consists of placing calcium hydroxide into the apical part of the tooth and covering the root apex with ProRoot material.

As a result of this, cement-like tissue is formed on teeth with non-viable pulp and the root tissue is gradually restored.

In the video, watch the technique of mixing and sealing root canals with ProRoot paste.

Instructions for using ProRoot MTA:

Restoration of perforation after resorption

- After applying the Rubber Dam, clean the root canal of sawdust and half-life products, using root canal instruments and irrigating the canal with solutions containing NaOCI.

- Place a temporary filling to close access to the cavity.

- After one week of applying Rubber Dam, remove CaOH from the root canal system using root canal instruments and irrigating the canal with solutions containing NaOCI.

- Dry the canal with paper points and identify the root canal defect area.

- Perform obturation of all canals in the apical zone from the established defect area.

- Prepare the Prorut AM material according to the attached instructions.

- Using the supplied application probe, place the material into the defect area. Compact the ProRoot MTA material into the cavity using a small amalgam plunger and a cotton swab or paper points. Attention: You can condense the material using a large ultrasonic nozzle without spraying water, at medium power.

- Make sure you have placed the ProRuth MTA correctly using the x-ray. If an adequate barrier has not been created, wash the ProRut MTA material with water from the defect area and repeat the procedure.

- Place a moistened cotton swab into the cavity and seal the canal with temporary restorative material for at least 4 hours.

- After 4 hours, or during your next appointment, using Rubber Dam, inspect the ProRuth MTA material. The material must be hard. If it doesn't, wash it and reapply.

- Once the ProRoot MTA material has hardened, obturate the remaining portion of the canals. ProRuth MTA should remain as a permanent part of the root canal filling.

Repair of perforation of lateral root canals

- After applying the Rubber Dam, clean the root canal of sawdust and half-life products, using root canal instruments and irrigating the canal with solutions containing NaOCI.

- Dry the root canal system with paper points and isolate the perforation site.

- Obturate all canals located apical to the perforation.

- Prepare the Prorut AM material according to the attached instructions.

- Using the supplied application probe, place the material into the defect area. Compact the ProRoot MTA material into the cavity using a small amalgam plunger and a cotton swab or paper points.

- Make sure you have placed the ProRuth MTA correctly using the x-ray. If an adequate barrier has not been created, wash the ProRut MTA material with water from the defect area and repeat the procedure.

- Place a moistened cotton swab into the cavity and seal the canal with temporary restorative material for at least 4 hours.

- After 4 hours, or during your next appointment, using Rubber Dam, inspect the ProRuth MTA material. The material must be hard. If it doesn't, wash it and reapply.

- Once the ProRoot MTA material has hardened, obturate the remaining portion of the canals. ProRuth MTA should remain as a permanent part of the root canal filling.

Root apexification

- After applying the Rubber Dam, clean the root canal of sawdust and half-life products, using root canal instruments and irrigating the canal with solutions containing NaOCI.

- Dry the root canal system with paper points and place calcium hydroxide paste in the canal for a week to disinfect.

- After one week of applying Rubber Dam, remove CaOH from the root canal system using root canal instruments and irrigating the canal with solutions containing NaOCI. Dry the canal with paper points.

- Prepare the Prorut AM material according to the attached instructions.

- Using the supplied application probe, place the material into the defect area. Compact the ProRoot MTA material into the cavity using a small amalgam plunger and a cotton swab or paper points.

- Make sure you have placed the ProRuth MTA correctly using the x-ray. If an adequate barrier has not been created, wash the ProRut MTA material with water from the defect area and repeat the procedure.

- Place a moistened cotton swab into the cavity and seal the canal with temporary restorative material for at least 4 hours.

- After 4 hours, or during your next appointment, using Rubber Dam, inspect the ProRuth MTA material. The material must be hard. If it doesn't, wash it and reapply.

- Once the ProRoot MTA material has hardened, obturate the remaining portion of the canals. ProRuth MTA should remain as a permanent part of the root canal filling.

Root apex filling

- Provide access to the root apex and resect it using a surgical bur.

- Using an ultrasonic tip, prepare a Class I cavity to a depth of 3 to 5 mm.

- Isolate the work area. Dry the root cavity with paper points. Stop bleeding with a sealant sponge or other suitable material.

- Prepare the Prorut AM material according to the attached instructions.

- Using the supplied application probe, place the material into the defect area. Compact the ProRoot MTA material into the cavity using a small amalgam plunger and a cotton swab or paper points.

- Remove excess cement and clean the root surface with moistened gauze.

- Make sure you have placed the ProRuth MTA correctly using the x-ray. ProRuth MTA should remain as a permanent part of the root canal filling.

Pulp capping

- Using the Rubber Dam, complete the cavity preparation using burs at high speed with constant water spray.

- If caries is present, remove it using a round bur in the handpiece at low speed, or remove it using hand instruments.

- Rinse the cavity and surrounding area(s) with 2.6 – 5% NaOC1 solution. Bleeding can be controlled with a cotton swab moistened with sterile saline solution.

- Prepare the Prorut AM material according to the attached instructions.

- Using a small ball-tipped applicator or similar device, apply a small amount of ProRuth MTA to the exposed area.

- Remove excess moisture from the work area using a dampened cotton swab.

- Apply a small amount of glass ionomer light-curing liner material to cover ProRuth MTI and cure according to the manufacturer's instructions.

- Etch the remaining cavity surfaces with 34%-37% phosphoric acid gel for 15 seconds. Rinse thoroughly.

- Gently dry the cavity, leaving the dentin slightly damp but not wet. Apply adhesive. Cure according to instructions.

- Complete the restoration by applying composite material.

- At the patient's next visit, assess pulp vitality. The vitality of the pulp should be checked every 3-6 months using radiographs.

This is interesting: Types of local anesthesia in dentistry, methods of administration

Reviews

If you had a chance to try ProRoot material on yourself as a patient, or you are ready to share your thoughts about this product from the position of a specialist, leave your review in the comments to this article.

Personal experience from use gives the reader the opportunity to form a more complete opinion about the product than the information given by the manufacturer.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags filling fillings

Did you like the article? stay tuned

Previous article

Features of the course and treatment of chronic fibrous pulpitis

Next article

Subtleties of practical dental restoration using the GlassSpan system

V. Warnings and Precautions

A.

Quickly close the lid of the container in which you store the powder. The powder is extremely sensitive to humidity.

IN.

The acidic environment in areas of inflammation disrupts the curing reaction of the MTA – Angelus material. Therefore, use cement only after acute symptoms have resolved and remission has been achieved.

WITH.

Do not use MTA – Angelus for root canal filling.

D.

When MTA – Angelus is removed into the periodontal tissues, the material is resorbed. However, removal of any cement may negatively impact the healing process.

E.

Store the material in a dry, well-ventilated place, protected from light.

F.

For use under aseptic conditions.