3353

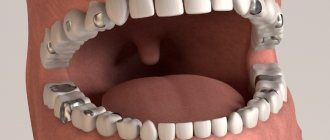

Dental implantation is a complex and time-consuming procedure that requires the dentist to have certain knowledge and skills, and consists of a large number of stages.

One of the intermediate procedures at the stage of restoring the integrity of the jaw row is taking impressions from the implants.

This is done with the help of special devices - impression transfers, which are fixed on the implant or abutment.

Concept and purpose

An impression transfer check is a part used in implantology to transfer the correspondence of the location of the implant fixed in the patient’s oral cavity to a working model.

It consists of two elements - a bushing, truncated cone-shaped with a cylindrical neck, and a mounting screw.

The material used to manufacture the device can be medical stainless steel or hypoallergenic titanium alloys.

Use during impression taking allows you to most accurately display the location of the implant or abutment in the jaw row , its inclination, and the position of the internal hexagon, if any.

This reduces the risk of making errors during the manufacturing and fixation of the selected prosthetic structure.

Taking impressions

During the implantation process, taking an impression of the jaw row plays a very important role. Obtaining a reverse image of the oral tissues in the area of the prosthetic bed allows you to create an exact copy of the patient’s jaw, which displays the location and placement features of the implants and the patient’s own teeth.

Based on the impression obtained in this way, a working model is made in a dental laboratory, which serves as the basis for the further design of a prosthesis or the manufacture of a specific orthopedic structure.

There are currently two methods of taking an implant impression:

- Imprint from the head of the product. The technology is most often used in cases where the decision on the shape and size of the abutment has not yet been made, as well as in the manufacture of a prosthetic structure fixed directly to the implant.

- Impression at the abutment level – used in case of preliminary selection and fixation of the abutment.

In addition, dentists note that in both of these cases, there are two options for taking an impression - open and closed impression tray .

The accuracy of the final result in both cases is the same, however, there are some features that require the choice of a specific type of procedure.

Features of zirconium abutments and advantages of individual products.

Visit here to learn more about the All on 6 implant method.

At this address https://www.vash-dentist.ru/implantatsiya/metodiki/kostnyih-materialov-v-stomatologii.html we’ll talk about the importance of bone material in dentistry.

Taking impressions

After the transfers are selected and screwed to the implants, a rigid or custom tray with impression material is brought into the oral cavity.

The mass hardens and the spoon is removed so that the transfers remain on the impressions. Then, in order to be able to recreate an exact copy of the location and inclination of the implants, implant simulators are attached to the transfers, and at the next stage, abutments appear on the working model, which are individualized to the structural features of the patient’s dental system and only now begin to manufacture crowns or other orthopedic structures.

As you can see, the process of prosthetics on implants requires much more effort, knowledge, practical skills and time, which naturally affects the final cost of denture structures.

To the list of posts

Material selection

The accuracy of making an impression of the jaw row for further implantation depends on various factors, the key of which is the quality of the impression material.

There are many requirements for the impression material, including:

- biocompatibility with oral tissues;

- high level of elasticity and viscosity;

- tensile strength;

- high resistance;

- sterility and non-toxicity;

- permissible degree of wettability and speed of solidification.

Based on these characteristics, experts most often give preference to silicone masses and polyesters.

In addition to the impression material, great importance is attached to the selection of a suitable transfer. Here the specialist pays attention to three factors:

- Transfer diameter. This parameter must correspond to the diameter of the gum former installed in the patient’s mouth.

When forming the level and relief of gum tissue using a temporary artificial crown, actions aimed at individualizing the standard impression device may be required. - Product height. To ensure that the subsequently manufactured prosthesis does not protrude above the remaining elements of the jaw row, the height of the device must correspond to the height of the teeth located adjacent to the missing one.

- Screw length. The optimal excess of the impression coping above the occlusal plane is 5-6 mm, based on this, the height of the screw should be selected.

Timing for installation of Osstem implants

First, the implantologist and orthopedist examine the oral cavity and also study images taken with a tomograph to identify the condition of the jaw bone tissue, the condition of the roots of the teeth, and the presence of any pathologies. A treatment plan is drawn up.

Before installation of the Osstem implant, professional teeth cleaning is carried out, as well as treatment of detected caries and other problems.

Next, anesthesia is performed and an implant is implanted into the jaw. With a one-stage installation protocol, a temporary crown is placed on it immediately or after 3-7 days, which after a few months (from 3 months to 3 years) is replaced with a permanent one.

In a two-stage procedure, Osstem implants are covered with gum, and after healing, which takes from 3 to 6 months, a permanent crown or prosthesis is placed.

The timing of implant installation can be different - from a single procedure, taking 0.5-1 hour, to a long one, involving several visits and a period of up to 3 years. It all depends on the specific situation and individual characteristics of the patient - the density and condition of the jaw bone, the number of implants that need to be installed, the complexity of the prosthesis, individual physiological characteristics that determine the rate of engraftment of the material, etc.

Impression of the implant

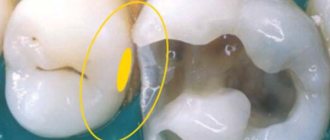

Before starting to take an impression of the jaw row during implantation, the dentist carries out a number of preparatory procedures:

- when the gingival tissue former is installed, the specialist removes it;

- An impression transfer is fixed to the head of the implant, selected taking into account the technique of the upcoming restoration, as well as the diameter of the gum former and abutment;

- an x-ray is taken to determine the correctness and accuracy of the device’s fit;

- The impression tray is tried on.

Further technology for taking an impression differs somewhat depending on which tray is used - open or closed.

Open spoon

The key feature of the open tray method of taking an impression is that the transfer check is tightly fixed in the impression material, so removing it from the jaw row requires turning out the fixing screw.

At the same time, this impression-taking technique allows not only to record the exact location of the implants, but also to obtain a clear image of the soft tissue relief in the area of the prosthetic bed.

The technology for taking impressions from implants using an open tray is as follows:

- The impression tray is tried on in the patient's mouth. It can be standard or custom made for the patient.

Most often, the product is made of transparent polymer material. This allows you to see the location of the screw and accurately mark the area for cutting holes. - Using a milling cutter or other suitable tool, a hole is cut in the spoon for the unhindered passage of the screw.

- Further steps to take the impression depend on the type of material used. So, when using a mass based on polyvinylsiloxane, it is applied around the devices, after which a spoon filled with the same material is placed in the oral cavity.

The use of monophasic impression material requires its introduction into the area of fixed structures using a syringe, as well as filling the impression tray with liquid mass and its placement in the jaw row.To prevent impression material from leaking through the drilled holes, specialists cover them with base wax.

- After the impression mass has finished hardening, specialists unscrew and remove the screws from the jaw line , after which they carefully remove the tray from the patient’s mouth. The transfers remain firmly fixed in the frozen impression mass.

- or temporary crown, which was removed before the procedure, onto the implant

After taking an impression in the laboratory, an analogue of the implant used is connected to the transfer check using a suitable screw, and an imitation of soft tissue is created around it.

After a thorough check of the position of all components of the structure, a working model is cast according to a standard protocol, on the basis of which the prosthetic structure will be subsequently manufactured.

The video shows the protocol for taking an impression with an open tray transfer.

Closed spoon

A distinctive feature of taking an impression using a closed tray is that after the impression material hardens and the product is removed from the patient’s mouth, the devices remain attached to the implants.

The procedure for making an impression is similar to the technique used in the case of an open tray, but has several distinctive features:

- The structure used when taking an impression with a closed tray can be made of plastic or a metal alloy.

As a rule, it has an outer body and an internal screw, so when fixing it is necessary to check the accuracy of its fit into the polyhedron on the implant before fixing the screw. - Before placing a tray with impression material in the oral cavity, it is necessary to isolate the hole located in the head of the screw fixing the device on the implant using temporary filling material or wax.

This will avoid inaccurate display of the screw surface on the cast, as well as further incorrect positioning of the structure.

The impression is made in two stages. After the initial insertion of a tray filled with impression material, its hardening and removal from the oral cavity, the specialist cuts off the formed interdental septa and other undercuts that may prevent the structure from being re-placed on the jaw row.

After applying the corrective mass to the tray, it is once again fixed on the prosthetic bed, due to which the final impression is formed.

After removing the finished impression from the oral cavity, the specialist carefully separates the transfer from the implant and fixes it in the resulting solid mass.

The previously removed and disinfected gum formers are placed in the intended positions of the implants, and the impression is transferred to the dental laboratory to create a working model.

Watch the video for the process of taking an impression with a closed tray.

Types of Osstem implants

What are Osstem dental implants made of? All of them are made of titanium - a metal with the highest biocompatibility, which does not cause rejection, which makes it possible to make from it not only dental implants, but also pins for bone fusion, and other elements for restoring and replacing lost fragments of bone tissue.

For Osstem system implants, a special hydrophilic surface has been developed, which is roughened by sandblasting, and then acid etched and treated with a calcium chloride solution. Thanks to this multi-stage treatment, the surface of the implant becomes completely similar to the surface of the bone, its wettability with blood increases, which gives faster growth of bone tissue around, accelerates healing and shortens the rehabilitation period.

The efficient thread configuration, which provides deeper penetration per revolution and the ability to cut itself, allows for less trauma to bone tissue and faster recovery. The Osstem Implant System company offers one of the richest lines of implants, which contains the possibility of installing the most suitable material in each specific case.

TS Series

A classic version, equipped with a double innovative corkscrew thread, which has high primary stabilization. The diameter of these models ranges from 3.5 mm to 5 mm, and the length is 6-13 mm. There are 4 varieties for installation in dense or soft bone tissue, for the lower and upper jaw, incl. for sinus lift.

TS SA

The surface of the SA implants in this series has undergone two types of treatment - sandblasting and acid etching. This led to surface roughness, the presence of microgrooves and craters, facilitating the fusion of the implant with the bone, or osseointegration, on which the successful implantation of the implant in the jaw and the speed of this process directly depend. TS II SA implants are distinguished by a simple installation protocol and the ability to control the penetration depth. They have a cylindrical body and deeper cavities in the apical (end) conical part, which enhances self-tapping abilities - these implants are designed to be installed in dense bone.

TS III SA implants have a smoother conical body shape with shallow self-tapping grooves in the apical part - an optimal design for installation in a fresh socket after tooth extraction. TS IV SA implants have an even more pronounced conical shape, which enhances the self-tapping effect - these implants are installed in the area of 6-7 molars of the upper jaw, they are suitable for soft bone tissue.

TS CA

The implants in this series are equipped with an SA surface, which is given highly hydrophilic properties. This is a step up from the regular SA surface. Treatment with calcium chloride leads to improved wettability, enhances cell aggregation on the surface of the TS III CA implant, stimulates their growth and reproduction, and therefore accelerates and improves its overgrowth with bone tissue. The shape of the implants and their mechanical properties are identical to the TS III SA series implants. Thus, TS III CAs take root better and faster, which reduces treatment time and costs.

Series SS III SA

This system assumes a one-step installation protocol, incl. immediately after tooth extraction. It is equipped with a polished neck, and the design allows the crown to be supported on the neck of the implant, and not just on the abutment, which enhances the stability of the entire structure and eliminates loosening and breakage of the abutment. Thanks to the special thread design, it can be installed even into soft bone.

The likelihood of the screw loosening and unscrewing, leading to breakage of the abutment, is minimal here - the chewing load falls on the implant, and not just on the abutment, due to which the micromobility of the entire orthopedic structure is reduced. Connecting the abutment to the implant with an internal cone and hexagon eliminates the gap and increases the tightness of the connection, so that saliva with food particles or fragments of gingival tissue do not penetrate inside - which means there are no foci of inflammation, bad breath, etc.

The conical shape of the body improves primary stability even in soft bone and makes the implant suitable for installation in the socket of an extracted tooth. The SS III SA implant has an SA surface formed by sandblasting and acid etching, which makes it rougher and more akin to bone tissue, accelerating implant healing.

MS Series

This series is solid cast with an abutment. It has a small diameter of 2.3 mm and is designed for use in thin bone with a narrow alveolar ridge. The implants themselves are characterized by high strength, do not bend even under high loads, and completely eliminate displacement of the prosthesis.

MS temporary

The implant is used for temporary prosthetics using the immediate loading method. Its design is specially simplified not only for easier installation, but also for easy removal. The installation is carried out between the places where permanent implants will be installed in the future and is designed for 6 months of use.

MS for narrow ridge

If the front part of the lower jaw is very thin and it is not possible to install a conventional implant, this model can be used. The structure of the thread allows you to more evenly distribute the load while chewing food. Excellent primary stability is ensured during the immediate loading procedure. This implant can be installed using one drill, which greatly simplifies and speeds up the entire procedure.

MS for removable denture

This implant is designed for installing removable dentures; the protocol for its installation is also extremely simplified. The model range allows the choice of implant taking into account the height of the gums.

ET III SA

The system is manufactured by Hiossen Implant, an American subsidiary of Osstem Implant. They are fully compatible with standard abutments, which gives the implantologist greater freedom of choice when making prosthetics. Their advantage is a combination of conical and cylindrical shapes, a special microthread, which provides the ability to fully control the direction of the material during surgery, as well as a sealed plug, which eliminates the ingress of saliva and the risk of inflammation.

From abutment

In addition to taking an impression from the implant, dental practice uses a technique for performing the procedure with a fixed abutment.

It can be carried out in two ways - with or without removing the transfer check from the oral cavity.

Withdrawal along with impression

In terms of technology, this method of taking an impression is practically no different from the procedure carried out when making an impression of the implant head.

This technique uses standard-type impression copings, which are fixed to the abutment with screws.

Standard trays are equipped with special holes that allow access to devices fixed to the abutment.

After the impression mass has completely hardened, the dentist turns the screw, then removes the tray from the patient’s mouth along with the impression structure, which is held in the solid material thanks to its anti-rotation and retention form.

Material and procedure for using a surgical template during implantation.

In this publication we will talk about the cost of express dental implantation.

Here https://www.vash-dentist.ru/implantatsiya/metodiki/tehnika-beskrovnoy.html you will find detailed information about bloodless dental implantation.

Remains in the mouth

The technology of taking an impression and leaving a transfer in the oral cavity is used extremely rarely.

The indication for its implementation is limited access to devices , as a result of which dentists have to use conical-shaped products that do not have retention properties.

The procedure for carrying out the procedure in this case is as follows:

- a standard one-piece transfer check is fixed directly to the abutment;

- the impression mass is distributed over an impression tray, which is placed in the patient’s oral cavity and left there for a certain period of time;

- After the mass has hardened, the spoon is removed from the mouth, the specialist carefully removes the device and fixes it in the frozen cast.

The procedure requires extreme caution, since incorrect positioning of the transfer in the finished impression can lead to errors in the further production of the working model and prosthetic structure

.